Today I cut out the NG30 high density foam plates that make up each side of the channel that the nose gear electric actuator will sit in. Not only do these plates start out with some of the densest foam out there (the H250 has a 16# density), but it gets covered with a 4-ply BID layup on each side of just ONE plate, so that’s 16 plies between the 2 plates. Also, in talking to Jack Wilhelmson about installing his landing gear actuator, I added 1 ply of reinforcement BID along the top curved portion of each NG30 as he recommended just to add a little robustness & strength [Note: Like many other components I’m building on this Long-EZ these NG30s are not to built to stock specs as spelled out in the plans but rather they follow the Davenport extended nose design, which obviously look different than stock plans NG30s].

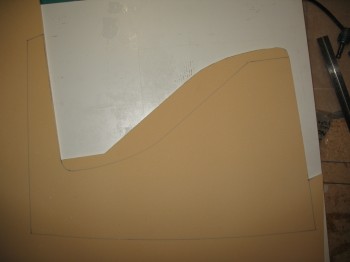

I trimmed down the sides & sanded them even so that the NG30s closely matched each other.

I trimmed down the sides & sanded them even so that the NG30s closely matched each other.