Although I did do some research and initial postulating/planning on the throttle/mixture friction lock and RAM air can butterfly pivot lever, my shop work today was all about working on the left pilot armrest storage compartment.

I decided on the top forward edge to install a clickbond vs a RivNut since I may put an Adel clamp in that area for the wires that will eventually go to switches on the small panel just behind the throttle quadrant. These switches will be used to control the 3 valve actuators for the oil heat system. To be clear, I could have most likely installed an Adel with a bolt into a RivNut as well, but using a Clickbond puts one less hole in the wall and gets the Adel up off the wall so a bit more clearance for it as well. Also, a second Clickbond provides another positive alignment guide for mounting the storage box… not that that should be a frequent occurance.

Regardless, I drilled out the mounting holes to 3/16″ and then taped up the flange to then mount taped up wide area washers and then the 3 prepped RivNuts on the aft side, and the Clickbond on the front edge.

After drilling out the RivNut holes in the sidewall and prepping them, as well as sanding and prepping the site for the Clickbond, I then mixed up some epoxy and floxed all the attachment hardware into their respective positions. I then used 2 spreader clamps to keep the RivNuts and Clickbond pressed firmly into place on the sidewall.

A few hours later I removed the clamps, tape and wide area washers, cleaned up the excess flox from the sidewall and remounted the storage bin.

Here are a couple shots of the new hardware securing the left pilot armrest storage compartment into place (sorry for fuzzy photo #2).

I had aligned and marked the storage compartment onto the inside of the armrest, and while the flox was curing I cut the storage access notch into the top of left armrest.

One thing I didn’t account for was the sizable gap that exists between the armrest and the sidewall, as I’m pointing to in the pic below. I think I do have just a tad bit of interference at the aft side of the storage compartment that is pressing the armrest inboard just a hair, exacerbating this gap. That being said, you can see much more of the inside (long) edge of the storage compartment wall than you should be able to… it should be pressed up tight against the inside edge of the armrest notch. I’ll of course work this minor but time-sucking issue.

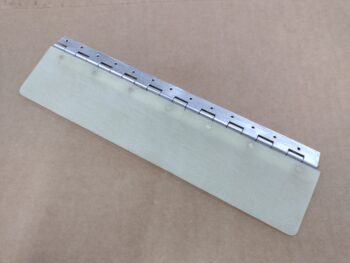

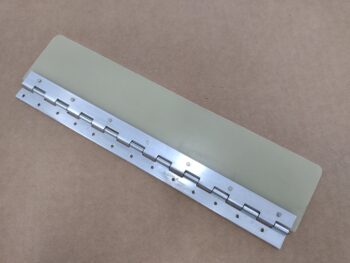

Also while the RivNut/Clickbond flox was curing I cut a 1/16″ thick G10 cover for the storage compartment as well as the hinge for it. I then riveted the two together.

Here’s an inside shot of the hinged G10 storage compartment cover.

Of course the sidewall/armrest gap is negatively impacting my hinged cover fitting as well, and will be another variable I’ll have to contend with as this all gets installed.

I’ll note that I’m looking more at functionality much more-so than I am aesthetics given that unless I’m actually accessing the armrest storage compartment, it will be hidden from view by the left armrest pad nearly all the time.

Before calling it a night, I did layup up a couple plies of BID on the Clickbond and also peel plied the layup of course. I didn’t grab a shot of that, but will tomorrow.

I’ll reiterate that I’m trying to get the left sidewall components installed and tasks completed as I work my back to the engine compartment. Tomorrow I plan to work more on this storage compartment, the left armrest and also the throttle/mixture friction lock.