Having figured out last night how much of the foam needed to be removed for glass, I started today by removing foam and micro from the very outboard edges of the canopy skirt underside.

I Dremelled both the channel groove and the edges and then sanded the bare glass part of the edges with 36 grit sandpaper.

I then spent a good half hour using the Dremel tool to remove the foam down to just shy of 1/16″ as best as I could. Of course that made quite a mess . . .

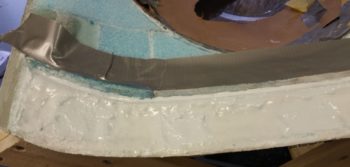

After getting the foam removed as evenly as possible –to make room for the 4 plies of BID– I then slathered up the foam surfaces with micro slurry first and then with some thick micro. On the front and side edges I used flocro, heavier on the flox.

I then laid up the 4 plies of BID just from the aft wall of the groove to the front edge of the canopy underside skirt.

I then peel plied the lay up.

I wanted the layup to be well on its way to being cured before I flipped it back onto the fuselage/glareshield, and it was getting fairly sticky (vs wet). But when I remounted the canopy –to ensure the canopy underside skirt layup would cure perfectly formed to the glare shield– something was amiss. I piled a bunch of weights on the very front portion of the canopy skirt, and it was laying down fairly well…. but it still seemed like 4 plies of BID in this configuration should not be that thick.

Well, I finally found a spot on the left side of the canopy frame where I could peer into the right underside of the canopy skirt. I didn’t see any peel ply and as I had suspected it meant the aft wall of the groove had been caught up into the groove versus hanging freely. I took all the weights off, had to lever the front of the canopy up… which I just lifted up around 6″ to then straighten out the glass in the groove. The issue was the aft canopy frame (i.e. turtleback) was pushing the canopy forward as the entire canopy settled into place, so there was very little spacing between the aft edge of the glare shield and the aft wall of the canopy skirt groove.

I tried as best possible to ensure all the glass was where it was supposed to be and then set the canopy back down in place. I then piled all the weights back up on top of it. It did seem better, but it may still need some tweaking after it cures.

While the canopy underside front skirt layup cured I then started on the initial sanding and shaping of the Metal Glaze that I slathered onto the roll bar-attached canopy gas strut mounting tab. The great thing about Metal Glaze is also probably one of its worst qualities in handling, it’s tough when cured so it took me over an hour just for this initial shaping.

Here’s a shot of the aft side initial shaping of the Metal Glaze. It rained most of the day today, so tomorrow I plan on getting the final shape dialed in at which point I’ll take the roll bar outside and hit the welded on canopy gas strut mounting tab with a couple coats of primer.

I also plan on getting the remaining front interior portion of the canopy glassed as well as the foam underside of the turtleback structure. IF I have enough time tomorrow I’ll also glass the aft internal canopy frame.