Today I started out by glassing the inboard and outboard sides of the outermost rib junction with the left strake leading edge. I also glassed the aft edge of the rib to the CS spar.

On the right I also glassed the aft edge of the outboard rib to the CS spar.

As I let the layups on the outboard ribs cure, I then finalized my markups on the wings for cutting out the ailerons.

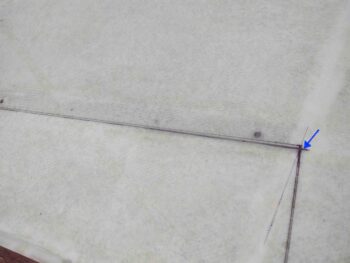

Here we have the underside of the left wing with the aileron outline marked for cutting.

I then rounded up my trusty “Fein” saw . . .

Ensured the top side of the wing was marked….

Ensured the top side of the wing was marked….

Uh… correctly! Upon double checking all the measurements I found that I hadn’t marked the inboard top corners at 5.9″ up from the diagonal seam, but rather 5.9″ from the 90º line to the trailing edge. This added about 0.1″, making the cut line a little further forward on the wing than it should be.

Luckily, using the ‘ol “measure twice and cut once” I found the issue and corrected it… again, on both wings.

After one last double check I then cut out the aileron on the left wing.

I did the same on the right wing as well. I didn’t get any pics of the aileron cutout as I was a little distracted upon finding a fairly decent sized delamination on the bottom outboard trailing edge area of my right wing.

Hmmm? Not sure how this happened. In the shot below I’m showing the approximate size of the delam with my hand. I’ll do some research and figure out the best way to repair this.

Marco and Chris Cleaver are flying down tomorrow for a visit, so it will pretty much be a no build day. I will take the opportunity to take a few hours to clean up the shop though.