Well, over the last couple of days I’ve been on the hunt for my original wing bolts. I have 6 long ones that somehow I had figured I would use with the reversed & secured bolt mod in the CS spar. But with all my notes and binders still in a bit of disarray from the tornado/hurricane that swamped my hangar, I have some struggles at times to reconstruct my build plans. So I’ll be honest, I have no idea how these long AN8 bolts (and I’m sure rather expensive) fit into the plan?!

I finally found the original four AN8-21A bolts for the outboard bolts, but still could not for the life of me find the interior two AN8-23A bolts for the inboard attach points. Since I need some -8 and -9 CAMLOC/SkyBolt studs for the thru-panel tabs I went ahead and pulled the trigger on another pair of AN8-23A bolts, plus a couple spares. In fact, I ordered some AN8-22A bolts as well just in case I need to add some washers to the wing bolts to shim the wings level.

With that debacle out of the way, and with time reclaimed from hunting everywhere (which I hate!), I got back into the shop to layup a ply of BID on each of the GIB area side sub-panels. I then peel plied the layups.

I then got to work on the heat/air duct that is situated just aft of the pilot’s seat on the left side. I might not have been clear in pointing out that I am attempting to finish up the last big tasks in the GIB area prior to building the strakes. In addition, if I can get a good day or two of weather early to mid next week I would like to get the majority of the cockpit painted also prior to building the strakes.

Besides sanding a bunch of the external surfaces for upcoming paint, and sanding the edges to mount to the sidewall and seat back, I also had 4 main tasks to accomplish to get the duct work ready for “permanent” install (I’m using silicone RTV to make it somewhat removable): Trim the GIB upper duct where the transition to the eyeball vent mounts to; add a clickbond to the upper face of the duct for a throttle/mixture cables securing adel clamp; patch a small divot in the edge on the top horizontal section; and patch a rather large hole in the duct where it terminates into the channel that transits the base of the pilot seat.

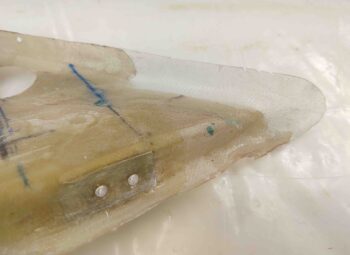

Here’s the very bottom patch of the heat/air duct where it terminates into the pilot seat back:

And a shot after all the glass had cured.

I also pulled the peel ply and razor trimmed the GIB sub-panels.

I then set them in place for a quick test fit and pic of each. The left side is jammed up against a cleco so it’s not fitting quite as tight as it will when actually glassed in place.

I was going to do some more glassing tonight, but I have to admit I wimped out due to just being tired. I plan to do a layup or two before I head up to Northern VA this weekend to visit some friends.