Today I had planned on starting out on the lower left strake skin foam core and get the pieces micro’d up and curing before pulling the peel ply and cleaning up the top right strake skin core… however, something big changed my work order!

According to the original FedEx tracking # I was due to receive my upholstered seat cores tomorrow (Sunday) but before I made it out to the shop they were delivered.

Here’s the first bag of upholstered bits that greeted me upon opening the box: the headrest pads and armrests. At first I thought they had gotten the leather colors wrong because the slate gray looked so blue . . . hmmm?

So out in the shop I quickly pulled the peel ply . . .

then razor trimmed the edges and cleaned up the right top strake skin layup.

I wanted to get the right strake top skin core in place to both test fit it and get this shot. I had to vacuum out the back seat and stuff all the wires back into the D-Deck/GIB headrest.

The headrest pad is temporarily taped in place, which is why it’s a bit off kilter here. I really like the lighter gray in the seats, and wish I could have gotten a bit more of it into the overall upholstery color scheme, but with them in place I have to say I’m extremely happy with how they came out.

I sat in the back seat for a good half hour and they are really comfortable. I’ll also reiterate that with the thigh support sump installed, at 5′ 11″ I’m near the upper limit of passenger height for anybody going on more than just a quick local flight. I’ll also note that when I sat in the back with the extended strake openings that my elbows naturally went into the strake openings…. so the “elbow room mod” is a must for passenger comfort in my opinion.

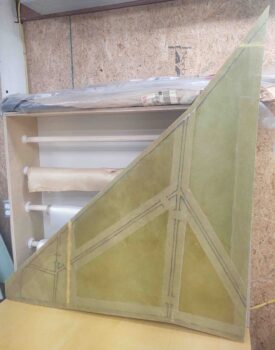

After test fitting the upholstered back seat cores (I’ll check out the front seat in another day or few, lots of stuff to reorg and clear out up there) I pulled out another sheet of 3/8″ Divinycell PVC foam and started fitting the bottom left strake skin core.

Here we have the bottom left strake skin foam core inboard edge along the fuselage marked and trimmed to fit. With a flatter vertical surface it’s actually easier to get a tighter fit on the bottom skin core than the top core as the longeron curves a bit on the top.

I then marked and cut the aft outboard triangular piece and the very small inboard front triangular piece and micro’d those to the big foam piece to complete the bottom left skin foam core. After it cures overnight I’ll take it outside like I did the top skin cores to mark and shape the aft bevel that mates up to the CS spar’s bottom beveled edge.

I’m tentatively calling Chapter 26 – Upholstery complete, given I still need to do a final fit check of the front seat cores. Also, cause I go easy on myself (wink) I planned for 3 days on the lower strake skins since I have the baggage area and GIB strake windows to contend with.