Thought I’d provide an interlude to the myriad of shop upgrade posts I’ve been making to have a discussion on the whole purpose of upgrading the shop in the first place: my Long-EZ build!

First off, Stacey was here visiting from Greensboro over the Thanksgiving holiday, and while she was here I definitely wanted to have her try out the Oregon Aero back seat cores. If I had been thinking I would have grabbed some selfies of both of us in the bird, me in front and her in the back seat, but alas I wasn’t.

Stacey –being a professional photographer– was thinking and she grabbed some pics of me messing about with the plane. Here I am at the start of our seat testing venture opening up the canopy . . .

And then apparently thinking of all the shop tasks I have to do before I get back to building… only reason I can think of for looking so annoyed. Ha!

And below I was enjoying how nice the seat cores feel!

On a serious, note: I’m 5’11” . . . or maybe just a hair under that now. The law of unintended consequences reared its head as I was testing out the GIB seat cores. I realized that with the thigh support sumps built in, there’s only so far down you can go before you hit that hard stop.

You see, in the original Long-EZ you were sitting on a simple sloped seat… kind of like a banana shape. If you were taller you could merely scooch your behind lower/forward, bend your knees a bit more and get your head lower into the canopy. Again, with a “hard stop” literally keeping your butt from sliding lower into the airplane, it makes for a height restriction at just about my height (not planned btw). Sitting normally I have about an inch or two to spare above my head with the canopy closed.

So, at my height sitting on the thigh support has me in a more upright position than in a normal (stock) Long-EZ. This naturally puts my shoulders higher and thus more in between the longerons vs. underneath the longerons. You can still game the system in my back seat by scooching your behind further forward ON TOP of the thigh support, but this leaves an open air gap under your lower back. Ironically, I think I may need to have a small lumber pad to put in place for my taller pax!

Moving on . . .

A few days ago I was part of a 3-way FaceBook message going on between Mike Beasley, Marco and myself. I was working on the shop so was in total lurk mode as Mike and Marco discussed Mike’s placement of his autopilot pitch servo. At the start, Mike was considering putting it just forward of the stick at the base of the instrument panel. Marco adroitly pointed out that when he installed his AP pitch servo that it messed with his Whiskey Compass big time, and was the reason why he mounted the servo as reasonably far away from the panel as possible (just aft of the front seat).

Mike played around with Marco’s proposed pitch servo location and eventually made it fit… good for Mike and collaboration worked to save the day again.

However, this got me to thinking seriously about my Vertical Card Compass and it’s relatively close quarters with my AP pitch servo not even a foot’s distance away. Yep, my compass is stuffed in the upper right hand corner of the panel and the pitch servo is mounted forward of that on the right side wall.

This potential issue got me researching and resulted in a phone call to Trio Avionics to confer with Jerry and Chuck on the matter. I learned that the Trio autopilot servos are primarily made of aluminum, with some plastic in the mix as well… which may be different than GRT or Dynon AP servos. Moreover, both Chuck and Jerry fly Long-EZs with both Trio autopilots AND vertical card compasses mounted in their respective panels, and neither of them have had issues with negative servo influences on their compasses.

They did however of course recommend that I install both compass and pitch servo and test out my configuration. That being said, I’m fully expecting to have to mount the compass in the upper left hand corner in a swap-out with my MGL clock/timer.

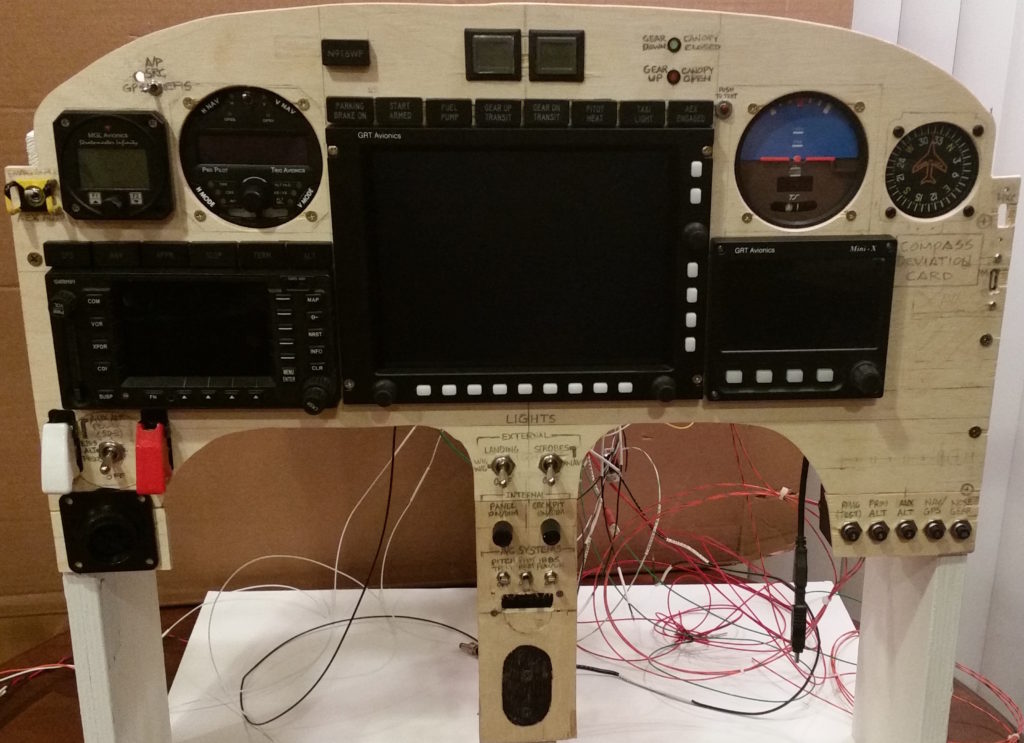

As I was assessing the probable position swap of my clock/timer and compass to opposite sides, I noted the minimal amount of space I had for anything in the upper right corner of the panel. It was then that I remembered that after making the decision to mount the Trig TT22 transponder in the right outboard strake, that I had moved the panel positions of both the TruTrak ADI and the Vertical Card Compass inboard about 1/4″. I grabbed an older (not the latest) cardboard panel to test if I was remembering correctly: Yep, I was.

I then spent the next couple of days –when I had a moment to think– pondering my courses of action. First, I could easily just move the TruTrak ADI and the Vertical Card Compass back outboard to their original positions. But to be honest, I like the better symmetry of these instruments’ new positions and don’t want to change that.

Then, upon further inspection it appeared that the real problem for fitting the Trig TT22 transponder was the GRT serial adapter. I then considered making up a 25-pin DSub to 25-pin DSub cable to allow the serial adapter to be placed somewhere other than on the front jack physically connected to the transponder unit. But that would require A LOT of work and a good bit of money for all those D-Sub connectors.

Thus, my final course of action and the solution I plan to go with will be to simply build and install a 90° bracket to allow the Trig TT22 transponder unit to be mounted on the right side of the TriParagon’s top shelf. I still have to check final clearances, but so far this is my plan. In addition, if I ever swap out my TruTrak ADI in the future, the screw pattern I’ll use for the bracket mount to the top shelf will be the same as the transponder bracket… allowing me to mount the transponder unit back in place on the top shelf whenever space allows.

Don’t go anywhere… there’s more!

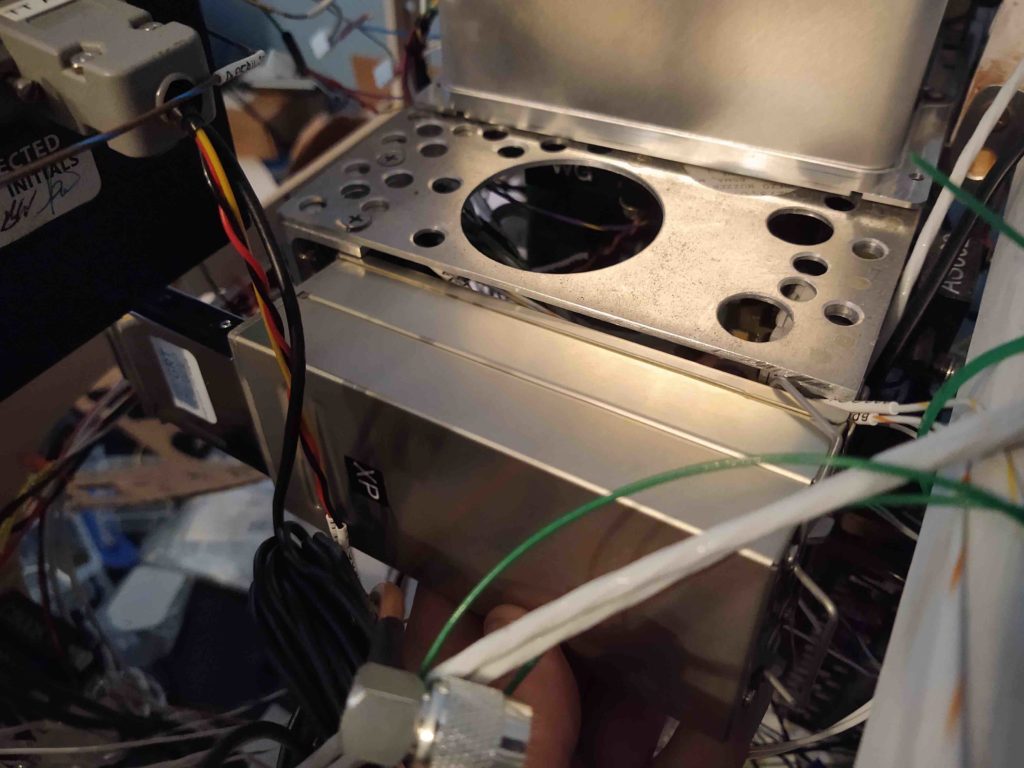

Over the past few days I’ve also been locating and collecting up all my tools, gadgets and consumables to allow me to build the wiring harness for the Trig TY91 COM2 radio (minus the 4 wires to the intercom). This will allow me to fire up the TY91 and have it connected to the GRT HXr EFIS so I can configure the COM2 control functions.

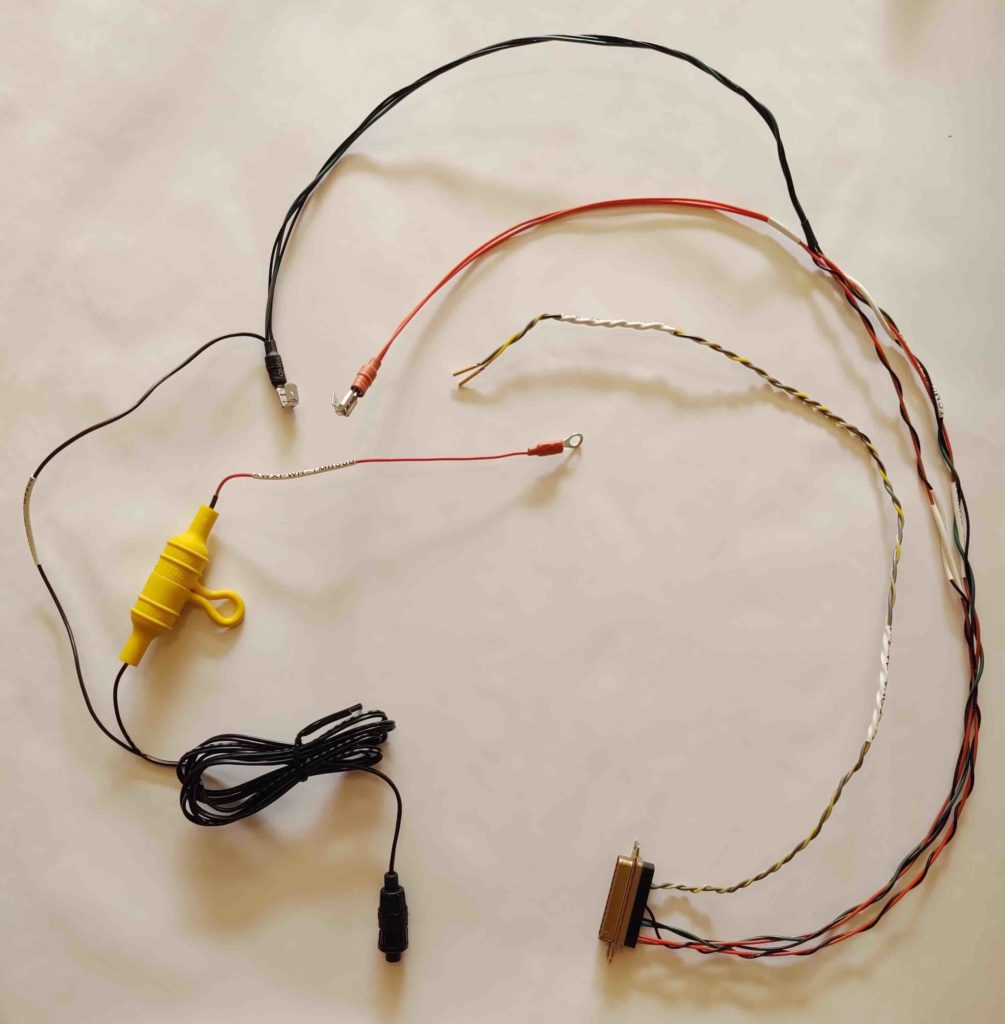

In addition to instituting a major switchology reconfiguration and doing a bunch of wiring diagram updates, I’ve also been taking a hard look at my ground busses and scrubbing those to make room for all the connections. I mention this because below is the WxWorx box power connections (left) included with the Trig TY91 COM2 harness (right). You may note that the ground wires of each component are combined together in, again, an effort to optimize my ground buss connections.

Over the next few days I will try to get my panel mockup repopulated and specifically the Trig TY91 COM2 radio connected and configured for control via the HXr EFIS. In addition, I do plan on firing up the WxWork system (although I don’t have a wx data subscription yet) to test out the Bluetooth connection with the Bendix/King AV8OR GPS unit.