I started out today by removing the bottom cowling –after extricating the hot glued popsicle sticks from the surface– and checking out the right side bottom cowling vertical 5-ply BID mounting flange I laid up (under duress!) yesterday.

It looked good so I pulled the peel ply and then immediately marked a line 1.2″ from the edge of the stock 1.6″ cowl lip.

I then trimmed the right side vertical cowling mounting flange and hit the edges with a sanding block.

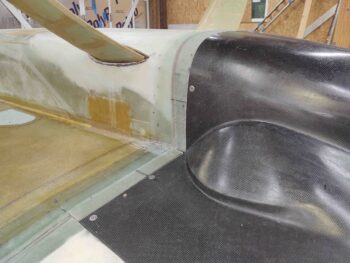

I then set the cowling back into place and ensured the edges were tight against each other at the aft fuselage/firewall to lower bottom cowling junction.

I then drilled a hole for a single CAMLOC on the sidewall, that will sit a couple of inches below the bottom edge of the armpit air intake scoop.

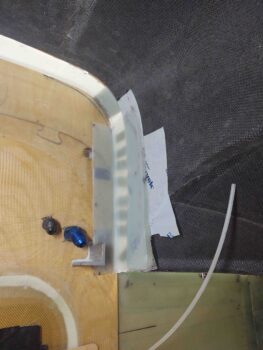

I then removed the bottom cowling and got to work installing the CAMLOC/Skybolt receptacle.

Here we have a lightweight stainless steel fixed Skybolt (CAMLOC) receptacle installed.

And a shot from the inside of the mounting flange.

I then replaced the bottom cowling and secured it with all the hardware to check the fit and integration of my latest installed CAMLOC . . . all looked good at this point.

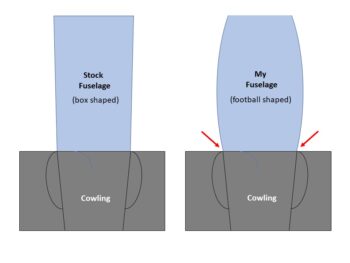

One minor issue I have, probably more cosmetic than anything else… although there might be a slight drag penalty, is that my fuselage is a lot more rounded than a stock fuselage, looking at it from either top or bottom. This means that the sides of the cowling tend to match a traditional straighter-sided fuselage shape vs my rounded fuselage shape. It reminds me of how hard-boiled eggs are served in those fancy egg holders, the egg obviously a rounded shape sitting atop a squarer shaped object.

Not surprisingly, this creates a small depression, if you will, at the junction of the aft fuselage/firewall to the front lower edge of the bottom cowling. It’s not horribly obvious or any type of challenge when the cowling sidewall is straight, as it is on my right side cowling. As a point of note, I will mitigate this offset angle depression as best possible when I micro-finish the fuselage for paint.

But when the cowling has a vertical bow to it, it makes this offset intersection angle even more pronounced…. thus requiring a few extra popsicle sticks and hot glue to help “flatten the curve” and better align the lower left vertical side of the bottom cowling to the aft fuselage/firewall.

After determining that my cowl-to-fuselage junction was acceptable, I then laid up my added 5-ply BID cowling mounting lip from the firewall face, across the inside of the original stock 1.6″ mounting flange, to then overlap onto the inside taped cowling edge a minimum of 1.2″. At the corner of the firewall and 1.6″ flange I added a nice flox fillet, just as I did on the right side, before laying up the glass.

I then peel plied the layup and left it to cure overnight.