In the military after an exercise or some significant event we would carry out what we called a “hotwash,” or a review of all actions to see where we could improve and gain efficiencies.

I can tell you that my mental hotwash on today’s 5-ply BID layup to bridge the gap between the aft fuselage/firewall to the front edge of the lower bottom cowling was not overly flattering or pretty . . . with a lot of woulda, shoulda, couldas thrown in there as well.

(sigh) Well, as we know: hindsight is 20/20…

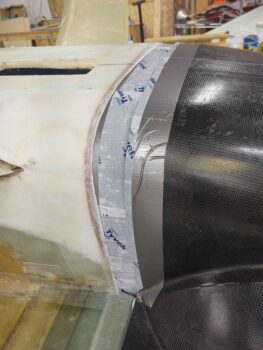

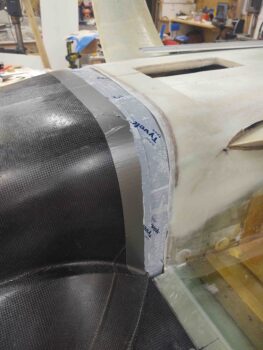

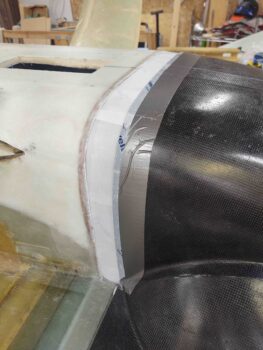

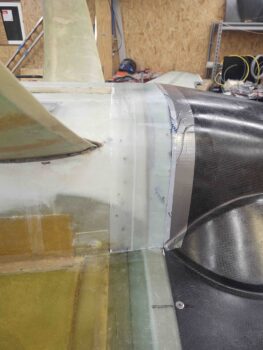

The goal was to get the original plans 5-ply BID cowling lip glassed into place with the glass even in elevation to the front edge of the lower bottom cowling.

The method to reach this goal was taping up some flexible cardboard pieces and then inlaying them in the gap betwixt firewall and cowling front edge. Thus, I taped up the cardboard and taped it in place from the inside.

My first mistake was that I didn’t test the final configuration of the form, since I left the aft side un-taped in order to get the peel ply slid into place. Although once the peel ply was in place and the forms taped up, it all still appeared to be acceptably good for the layup.

The problem is that as the layup of the 5 plies of BID progressed, the tape securing the tape covered cardboard form just was not securing the form as tightly or as closely to the inside of the cowling as I needed.

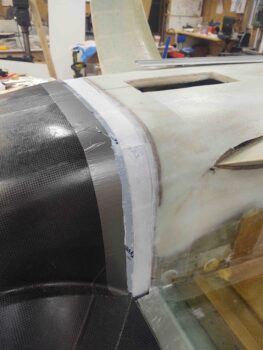

After the layup I consider ripping it all off and trying another approach. But then as I assessed it I figured that it is fairly close and that I would simply call this yet another iterative process, and this would now be step 1 of how many steps? . . . TBD.

But it is a step in the right the direction.

It’s just not the single step I had hoped for.

Here’s a look at the inside of the cowling and firewall, with the copious amounts of tape and even a clamp employed in spreader mode to help keep the form pressed up tightly against the cowling… but not too tightly to deform the cowlings bottom shape.

So tomorrow will begin the mini-journey, and yet another iterative creative task, to get the firewall cowling flange dialed in so that I can get the subsequent added flange glassed in to allow me to secure the bottom cowling to the aft fuselage/firewall.