Today I started out with a lot of juggling between updating my various 3D modeled parts in Fusion 360 CAD —and 3D printing those parts— and working on buying a bunch of various stuff to move forward with the build.

As for parts, I separated out the cable mounting tab from the primary throttle cable bracket in Fusion 360 CAD, since this actual mounting tab will be secured to the primary bracket body via two 10-32 countersunk screws. After I finished modeling up the throttle cable mounting tab I then 3D printed it.

I also extended the primary throttle cable bracket about 0.7″ and added the screw mounting holes to the bracket. Note that I also lessened the angle of the cable mounting tab so it doesn’t point upwards nearly as much.

Here are another couple shots of the latest version of the throttle cable bracket.

Again, in between working my 3D mockups and actual (below) parts, I was reaching out to Frank at California Push-Pull Cables to collaborate on my cables to allow me to then place the order. I was also building parts, hardware and aluminum stock orders at ACS, McMaster-Carr, and Wick’s Aircraft.

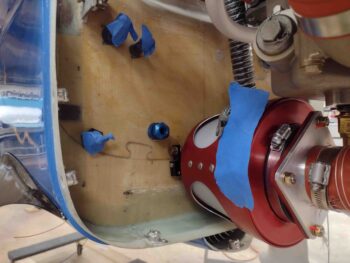

After the lackluster yet promising initial trial of my GIB seatback bulkhead pass-thru I modified it heavily and 3D printed the new version.

This one fit much better. Note that I put male/female alignment pins/holes on the two halves so I can snap the halves together around the cables and then slide the assembly into the GIB seatback slot. I would have gotten a pic of Version 1 of this thing, but the halves fell apart and back into the hell hole…somewhere… which I made a note on my task list to retrieve!

Late in the afternoon I finally got Frank on the horn and after a brief Q&A period, I pulled the trigger on 3 cables: Throttle, Mixture and GIB Throttle.

After submitting my order to Push-Pull for my cables, I then again worked orders for various parts and hardware, but specifically wanted to get the aluminum for the cable mounting brackets in hand so I can get those made. I had planned on buying a 2″ x 2″ x 1/8″ angled 2024 piece from ACS, but honestly their shipping on metal stock is so outrageous I pulled the plug on that…. although I did submit the remainder of that order for a bunch of other stuff.

After more digging around, I finally made the call to use 1/8″ 6061 T6 that I have on hand for the mixture cable bracket, since there’s really not a whole lot to this bracket. For the throttle cable mounting bracket I ordered a 1-foot length of 1.5″ x 1.5″ x 1/8″ 7075 aluminum angle from McMaster-Carr.

Tomorrow I plan on submitting an order with Wick’s Aircraft for the cable Heim rod ends since ACS was out of them and Push-Pull Cable would have had to source them as well.

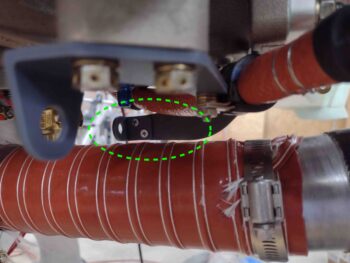

Back in the shop I drilled the mixture cable hole in the firewall out to about 5/8″ to allow installing the aluminum Cable Safe II bulkhead pass-thru.

Here’s a shot of the mixture cable firewall pass-thru installed. Once I fill the holes, clean up and organize the right side of the firewall, I’ll drill out and install the throttle cable firewall pass-thru.

My last task of the evening was to remove the -6 fuel hose from the engine to pressure test it to ~130 psi. It passed with flying colors and thus far all my hoses are good to go.

Tomorrow, Valentine’s Day, will be another short day since I’ll be spending the afternoon and evening in the very awesome town of New Bern, NC. That being said, I do plan on getting as much done as possible during the first half of the day.