Well folks, it finally happened… I finally hit the wall space-wise in my bird. I’ll get to that just below.

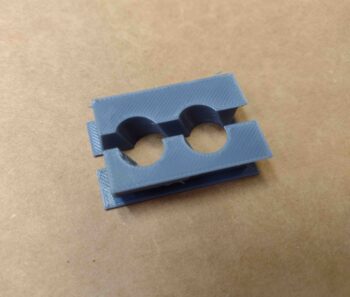

First, here is the last 3D print of the late evening last night: my latest version of the GIB seatback bulkhead cable pass-thru. I would say clamp but the purpose really is simply to protect the throttle and mixture cables as they traverse the treacherously sharp gnawing edges (ok, over time) of the GIB seatback. Which goes to show you that you just simply can’t trust those GIBs!

Clearly this is a clamshell design to wrap around the cables and then wedge in tightly to the slot opening in the GIB seatback. Of course I do plan on using some silicone RTV or something to help keep it solidly in place. I’ll reiterate as well that this is not a mockup and that this part will actually be 3D printed in PETG plastic.

The mockup part that was printing while I finished up the blog last night was the extended version of the throttle bracket. I extended this forward due to repositioning the throttle lever on the fuel injection servo so that it had a better rotational track with the throttle cable rod end.

The 3D print had some issues with printing out the actual cable mounting tab, but I’m not really concerned about that… I just want the data on how far the end is from the mid-travel point of the throttle cable rod end and clearance with the fuel hose.

I then spent a good bit of time on the my major task of the day: running the mockup throttle and mixture cable through the hell hole, through the GIB seatback, through the GIB left armrest, through the GIB forward compartment, and finally through the pilot seatback. Every one of these positions required assessments and decisions on how and where the cables would, could and should be run.

After drilling a 3/4″ hole in the pilot seatback —in seemingly the only spot that I could— I then ran the cable forward to the pilot throttle quadrant that I just temp installed for this purpose. I then used this bowden cable as a mockup for the respective mixture, throttle and GIB throttle cables to obtain the measurements for each cable.

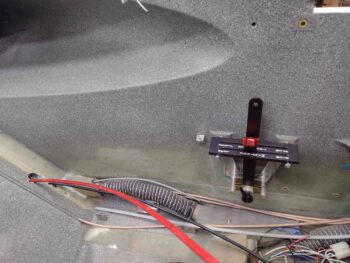

Below is the cable run for the GIB throttle quadrant. Yes, it looks a bit long here, but this is after I measured this length previously.

Note the run of the cable(s) across the face of the oil heat exchanger since I had no other route to take to get the cables to the pilot throttle quadrant. If I ran the cables above the black carbon fiber covered heat exchanger, and through the pilot seatback, it would have resulted in the cables not entering the pilot armrest under the top of the actual armrest.

Thus the title of this blog… I seriously had no where to go with these cables except where they are shown in this pic below. Thankfully my cables will be black so they’ll blend in with the heat exchanger and hoses to it. Moreover, I’ll try to minimize the inboard intrusion of the Adel clamps by squashing them down as much as possible.

My goal today was to get the lengths of each cable measured. I was able to do that. Tomorrow my #1 goal is to get the cables ordered with the Push-Pull folks. Hopefully I can get that done as well.