Today was as much fact-finding and R&D as it was actual building in prep for ordering the throttle and mixture cables.

Since Marco’s Ellison Throttle Body gave up the ghost and he fairly recently upgraded to the same throttle quadrant and Silver Hawk EX fuel injection system that I have, I wanted to get the numbers he used for the cable rod end travel for both his throttle and mixture cables. As an aside, I thought that Alan at Silver Hawk (Precision Airmotive) might know, but he only had degrees for each lever and told me to do higher level math (that jokester!).

Conclusion: the magic number is 3″… at least that worked for Marco on his flying bird, and is exactly what I got for the throttle and only 1/4″ off from the 2.75″ I calculated for the mixture. Going 3″ on both puts the distance from cable attach to lever at 7.38″ on the mixture side.

I decided to go with 2″ x 2″ x 1/8″ angled 2024 aluminum for my mixture bracket (1.5″ x 1.5″ x 1/8″ 2024 for throttle bracket) so starting off I needed to see if I could squeeze out another little bit by moving the actual attach tab forward 0.38″… I did with just barely enough material.

Since I was updating/finalizing the dimensions on the mixture cable bracket as I whittle down my cable numbers, I then went ahead and added about a 2″ inboard jut-out to the bracket to allow me to attach another Adel clamp to the -6 fuel hose.

Since the fuel hose is angled 30º-ish the Adel clamp bit into the radiused but square corner of the bracket jut-out. The offending 1/8″ bracket jut-out corner that was digging into the Adel clamp also served to push the entire -6 fuel hose towards the right a hair and closer to the throttle cable bracket. Clearly my addition needed a slight trim and reconfiguration.

I spent a good amount of time looking at my throttle quadrants —a 2-handled front pilot’s quadrant and a throttle-only GIB quadrant— to assess if I could squeeze in a throttle handle into the back seat. It’s always made me a little nervous having only one set of throttle controls up front and having the GIB screwed if somehow the pilot gets incapacitated. This time spent translated into me spending 45 minutes or so sitting in the back seat with a tape measure trying out and postulating a myriad of possible install configurations.

I spent a good amount of time looking at my throttle quadrants —a 2-handled front pilot’s quadrant and a throttle-only GIB quadrant— to assess if I could squeeze in a throttle handle into the back seat. It’s always made me a little nervous having only one set of throttle controls up front and having the GIB screwed if somehow the pilot gets incapacitated. This time spent translated into me spending 45 minutes or so sitting in the back seat with a tape measure trying out and postulating a myriad of possible install configurations.

I kicked around the idea of using the same 5/16″ 2024 tubing that we use for our canopy catch rods, but with the Oil Heat Exchanger mounted to the lower left sidewall I have zero ability to run a straight tube that would allow me to slave a throttle quadrant off the front throttle handle. After many machinations, I finally concluded that there is just about zero room to attach anything to the front of a throttle quadrant on the left side wall in the back seat compartment.

But what about from the aft side? Hmmmm. Well, no matter if I have a GIB throttle or not, it’s mandatory that I get at least 2 cables from the engine compartment to the front seat left armrest. Thus, sneaking in one extra cable through the pilot back seat along with the other 2 is very doable. It would then simply make its 180º-ish turn under the GIB left armrest and mount at an angle just under the front of the armrest. It would also mean converting my single-handled throttle quadrant to a reverse configuration where it pivots mid-lever vs the bottom of the lever, but again I think it’s very doable. More to follow on this.

With my quadrant connections mentally good to go, with even more research to find sources for the Heim, etc. rod ends (ACS is out of all the required stuff!), I then got back to work in the shop finalizing my mixture cable pass-thru point on the firewall. After checking in the hell hole for clearance ….

And quadruple checking my angles, I then drilled the mixture cable starter hole.

A closer shot of drilling the mixture cable pass-thru hole in the firewall.

I then ran a 1/4″+ bowden cable I have on hand through the firewall to check out the angle of the cable install… this cable is fairly stiff so I think it’s a good mockup for the mixture cable.

I then assed the cable runs inside the cockpit. Notice that the bottom slot on the left side of the GIB seat is crammed full of goodies. And if ya’ll remember, that slot sits right in front of the forward gear mount extrusion at the front corner of an angled seatback. In other words, I can barely get my fingers up in there to tell if there’s any spare room, let alone drill any extra holes to run cables… especially cables that will require nearly a 1/2″ diameter hole to run the cable through.

The bottom line is that the only real option is to use the upper slot of the GIB seat to run the throttle & mixture cables. Clearly there is a narrow edge around the perimeter of this slot that can rub against the cables over time.

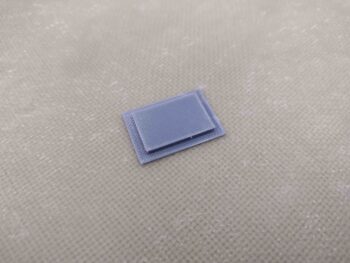

After measuring the slot, I drafted up a test coupon that will be the beginning of a seat bulkhead cable conduit/clamp to secure and protect the cables transiting the back seat opening.

Here is the initial test fit of the cable transit block for the GIB seatback slot.

Here we have the mixture cable (mockup) transiting the firewall from inside the hell hole.

To further nail down the configuration, design and dimensions of the throttle cable bracket I finally needed to bite the bullet and reposition the fuel injection servo’s throttle lever. This requires pulling a cotter pin out of the castellated nut and replacing that cotter pin once the nut is re-torqued back into place. I have this pin loaded up into my ACS cart as well as an entirely new specific $7+ nut for the mixture lever as well.

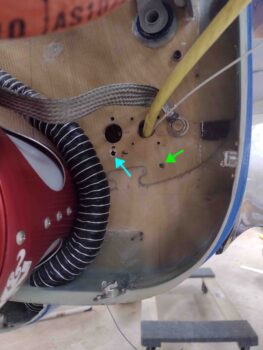

After another good 45 minutes of hell hole recons and playing musical chairs with firewall pass-thru components, I drilled the right side hole for the throttle cable. You may note the pass-thru hole I’m drilling is right below a large hole that was where the Blue Sea bulkhead cable pass-thru for the Alternator’s B-Lead was located. Clearly this move is to have the most optimized (as possible) elevation and position of the throttle cable pass-thru on the firewall.

A shot of the initial firewall throttle cable pass-thru hole, captured through the throttle cable bracket attach tab.

Below we have the lower right firewall, with the new pilot hole for the throttle cable pass-thru (light blue arrow) and the relocated position for the Alternator’s Blue Sea cable bulkhead pass-thru (green arrow). I’ll fill in the holes above the throttle cable hole and probably slap a ply a BID each side of the firewall to finalize the hole fill.

While I was messing around with the throttle cable firewall pass-thru hole positioning and drilling, Bob was whirring away 3D-printing Version 2 of the new mixture cable bracket… replete with the inboard extension to mount a fuel hose-securing Adel clamp.

Which I then test fit into place. With that inside aft corner cut at an angle on the bracket extension, it allows for a much closer fit with the Adel clamp and minimizes pushing the fuel hose out of position.

Note the clearance on the far side between the fuel hose and the throttle cable bracket… much better than when the hose was being pushed much closer to the throttle cable bracket.

Now, the slight height/elevation difference between the bracket and the Adel clamp will mandate the use of a spacer between the bracket extension and the actual Adel clamp. Other than that, it fits a treat!

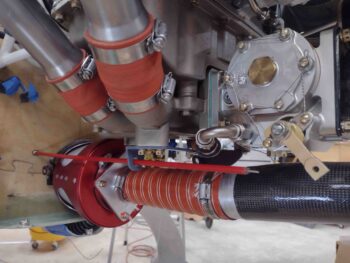

Note the Sniffle Valve in the background (near center of pic)… this is now installed after I gooped and torqued it to spec.

A closer shot of the now officially installed Sniffle Valve… another task off the list!

I will further note that I have an updated throttle cable bracket mockup 3D printing as I post this… and after that finishes I’ll 3D print the prototype of the GIB seatback bulkhead cable conduit/clamp.

Tomorrow my goal will be to ascertain the no-kidding dimensions for the three throttle and mixture cables: 1) fuel servo throttle lever to pilot quadrant, 2) fuel servo mixture lever to pilot quadrant, and 3) pilot quadrant throttle lever to GIB throttle quadrant.