I headed out to the shop today to specifically get the cylinder #2 fin standoff supports made.

But as I was looking over the already installed CF inner cylinder baffles, I noticed some gaps on the aft left cylinder #1 baffle. It just wasn’t fitting right. I pulled the baffle off, cleaned up the glue and then went through a series of test fits. I found the culprit being the first 2 outboard fins (note the pointer in the pic). I trimmed about 1/16″ (0.060″) off the rounded corners of these fins and also angled them down on the outboard edge of each fin. I also aggressively sanded the inside of the baffle at the mating area with these fins.

It’s hard to tell in this pic of course, but the baffle fit is MUCH better and sits significantly tighter on the cylinder.

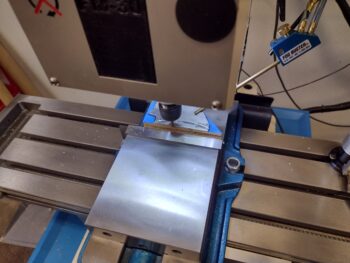

With my unplanned and impromptu baffle redo out of the way, I then finally got around to machining the inboard fin standoff support for cylinder #2… out of some scrap 0.090″ thick 6061.

With the inboard standoff support (the larger of the two) complete, I then set up and milled the outboard standoff support.

Here we have the cylinder #2 outboard (top) and inboard (bottom) fin standoff supports ready for attaching to the aft cylinder wall.

And here are the cylinder #2 fin standoff supports glued in place.

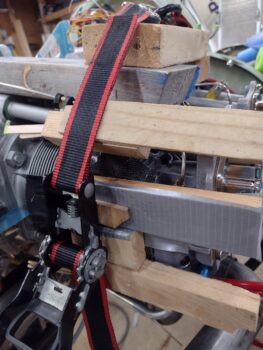

I had to run into town to grab a few things at the store and stop by Jess’s place for a couple of items as well. After a few hours time to let the standoff support glue setup I then glued the right aft baffle in place over and around the standoff supports.

Today’s tasks knocks out all the major front and aft CF inner baffle installs. Tomorrow I plan on getting the right side top inter-cylinder baffle (the “Star Trek Enterprise baffles”) glued into place. Then it will just be the top inboard inter-cylinder baffle pieces that need to be trimmed and set into place.

Trust me, if you’re tired of reading about these baffles… I’m tired of installing these darn things. I want them DONE!

Pushing forward.