I had some decent build plans for today but it turned out to virtually be a non-build day in most regards. Last night I got an email saying that our monthly EAA meeting was this morning at a local restaurant. I texted the new Canardian in the area, Guy Williams, about the meeting since I wasn’t sure if he was on the email.

I also received a text from my friend asking if I could watch her daughter, aka “my little buddy,” while my friend went to a doctor’s appointment. No problem there either.

After the EAA meeting, Guy and I went to the airport to check out his Long-EZ. It’s a beautiful classic built in 1982. He and his dad, who owned it for many years before Guy took ownership, converted it from an O-235 to an O-320. Guy moved out here this summer from Tehachapi, CA… home of Marc Zeitlin and Mike Melvill. Thus Guy clearly had plenty of expert help on hand to assist with engine conversion, etc. on his Long-EZ. And of course it’s great to have another Canardian at the airport, especially one of the Long-EZ persuasion!

Now, in my mind I figured a doctor’s appointment would take an hour or two at most, and although I only know that it was NOT anything serious, this appointment ended up being over 4 hours… that had me on kid-watching and entertaining duties. By the time I got home it was well past 4 pm and I was due to have a dinner/evening out with Jess… so my already shortened work day was severely truncated by events that plopped onto my schedule just the night prior.

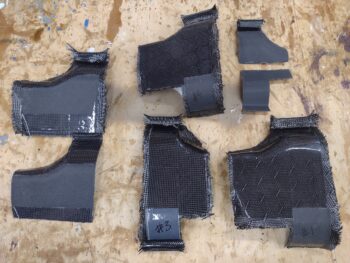

Out in the shop I pulled all the laid up baffle segments off their respective molds and pulled all but one piece of peel ply (only because it has such clear baffle edge trim markings on it). I can tell you the added 6-8 hours of cure time with these baffles on the molds was felt significantly as they were MUCH harder to get off each mold!

Here’s the tally, starting CW from the lower left corner:

– “Old” top outboard wide inter-cylinder baffle (to be joined with narrow baffle segment)

– Opposite side of above, just laid up… now just need to layup narrow parts for these

– “Old spinner print CF” end baffle now relegated to duty on front of cylinder #4

– 2 pcs for cylinder #2 aft end narrow baffle that will get middle fin extension area added

– New “spinner print” aft end baffle with much better looking CF for cylinder #1

– New narrow end baffle for front side of cylinder #3

Also, before I headed out to the shop I quickly drew up in CAD and then 3D printed an initial template for the cylinder #2 fin extensions and associated baffle curve over these extensions. Here’s the result that I temporarily taped up in place.

And an idea of how the top and bottom baffle segments will get melded with the upcoming semi-circular cylinder fin standoffs.

With that, it was time to get inside, clean up and head out for a Saturday evening with Jess. Tomorrow I definitely intend to get at least the 2 partial narrow baffle segments glassed up for the other half of the top outboard inter-cylinder baffle assemblies that need to be floxed together back-to-back to make up those baffle segments. I would also like to get some machining done, with the baffle extensions getting made to confirm the configuration for me to then “glass” (CF) up the gap on frontside cylinder #2 baffle.

Moving forward!