Today was a very cold day weather-wise so I didn’t do any layups in the shop since the preferred working temp for the HTR-212 hi-temp epoxy is a minimum of 80° F. And I just didn’t want to have to jump through all the hoops of using heat lamps and heaters, etc. to keep the layup and curing areas warm.

I did mount the bottom cowling to check out my latest clearance protrusion. Not something that I of course prefer to have present on the bottom cowling, but a must to provide necessary clearance with the #2 cylinder exhaust pipe.

Hindsight is always 20/20, so knowing and seeing now what I couldn’t really get when I started, I could have easily taken this cowling bump about 1/4″ inboard and about 0.150″ less in height at the vertical edge to make it a bit more diminutive in the airstream. Hard to see all that when you’re visualizing and just going off the marked up Sharpie borders of the exhaust pipe. Yes, I may have a bit more constant drag caused by this form, but I also alleviate any contact between exhaust pipe and lower cowling.

On the inside I checked not only the exhaust pipe clearance, but flipped the EGT probe securing hose clamp around 180° so that the screw portion of the clamp was facing forward. I then checked the clearance under the hose clamp screw and it’s right about 0.47″… close enough to 0.5″ clearance so I’m calling it good. That of course provides plenty of clearance for the exhaust pipe itself.

This hose clamp repositioning also gets that clamp screw out of the line of fire to allow freer access to the spark plug for install/removal, but then also adds to the bottom depth of the exhaust pipe as I showed in this pic a few posts back.

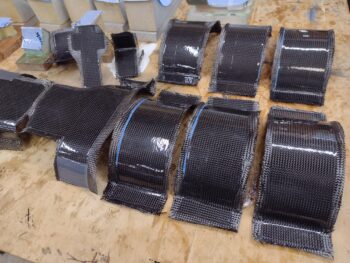

I then spent a bit of time pulling the now cured Round 1 inner baffle 2-ply CF layups off their respective forms.

Here’s a closer shot to show the weave of the CF. Thankfully not only did the parts come off the forms easily enough, but they didn’t tear up the forms… easily allowing another round (#2) of layups to hopefully knock out all the parts required for these inner baffles.

With that being said however, tomorrow is forecasted to be even colder than today, so I will probably get some much needed personal stuff done and forego shop ops altogether, other than just trimming the excess CF off these parts.

Pressing forward… haltingly!