I spent a good majority of the day 3D printing out the air induction tube, that actually ended printing early the next morning. I spent nearly 5 hours on the first two 3D prints trying to print out both the Air Induction tube mounting bracket to the Fuel Injection Servo and the tube itself, which I had as the thin-walled tube that it would be in physical actuality.

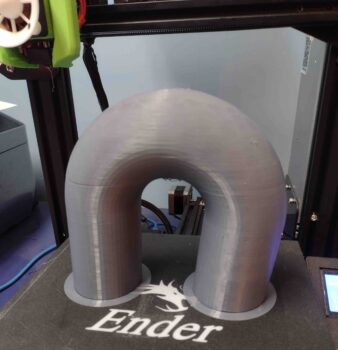

However, the tube walls were too thin and my attempts at 3D printing it were proving problematic. I then decided to print a more solid version of the tube, which worked… and which took over 12 hours to print.

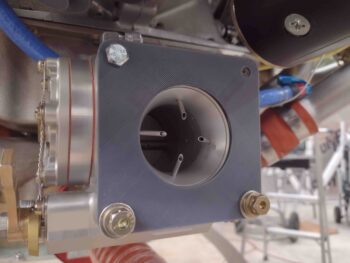

From the first two failed 3D prints I did get a couple of good mounting brackets mockups for the air induction tube. The bolt holes are aligned correctly and both the internal and external edge dimensions are good as well.

Tomorrow I intend to check this latest version of the air induction tube to check its clearance with the inside bottom surface of the lower cowling. I’ll adjust fire from there in my effort to get the air induction system plumbing installed.