I’ve been doing a bunch of holiday prep since I’ll be heading out of town to spend Christmas with my daughter, son-in-law and grandkids.

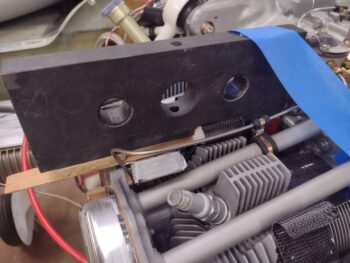

My goal for the build today was to get the left side top outboard inter-cylinder baffle glued into place —including the crazy machinations in securing it in place during its cure!— and then move onto machining the right side cylinder #2 aft standoff supports and get those glued into place to allow me to then get the actual aft baffle attached tomorrow (after the 18 hour cure cycle).

Well, I did get the left side top outboard inter-cylinder baffle glued and secured into place.

Then, before I jumped into machining the cylinder #2 standoff supports, I cleaned up all the inner baffle forms, carefully packed them back up in the box they were sent to me in, and then ran downtown to send them back. Clearly the chapter of this build involving these CF inner baffles is ever so slowly coming to a close.

Even a bit slower after the events that ensued upon my return to the shop.

I worked out the CAM post processing for the cylinder #2 aft standoff supports and prepped some 0.090″ 6061 to machine for the creation of the standoffs. Not having used the milling machine in a few months, it required a good 45 minutes of TLC in cleaning and oiling before I got started. I also forgot a couple of weeks ago I had a pressure line inside my compressor closet burst, which needs to be repaired… so I had rig up another compressor to handle those duties (my milling machine quick tool changer, chip removal mister and air blaster are all on one of these lines).

Once ready to go, I learned that my handy hack of using super glue and blue tape has its limits: a thicker material such as 0.090″ with a smaller footprint just can’t hold up against the pressure of the end mill biting into the corner as it cuts… I tried this method twice with no joy.

At this point in the evening is was late and after multiple iterations and all the required prep, I figured I will have to do some more Neanderthal machining by cutting these things out with my Dremel Tool. Jess was due over in about an hour to make us a nice dinner, so I decided to kick this can down the road until tomorrow since I would most likely only get one of the two standoff supports manually cut out and shaped (I still have a thought on machining standoff #2 which I’ll attempt tomorrow). Only gluing one of the two standoff supports into place clearly wouldn’t put me any more ahead with the cure cycles required. So I called it a night…