Today I machined a new, thicker mixture cable bracket.

The bracket is thicker overall, 3/16″ versus the previous 1/8″ bracket, but the cable mounting tab is significantly beefier, and that’s what I was focused on.

Here we have the top side of the new mixture cable bracket machined.

And here is the bottom side beefier-than-before cable mounting tab that I mentioned above. To be clear, I think a 1/8″ thick tab overall would have been strong enough, but this tab here is the main thing I wanted to be more robust.

A bit later, after some judicious filing and cleanup, here is the 3/16″ thick 6061 mixture cable bracket.

And a couple more shots . . .

I took the “old” bracket off and compared it to the new one. Clearly the new one just looks a lot more robust.

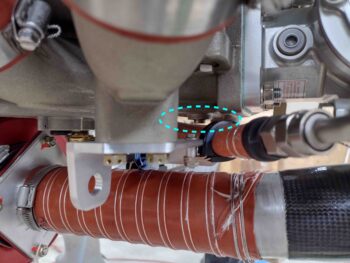

I then test fit the new mixture cable bracket into place. It too fit like a champ.

As I noted in a previous post, the extra 1/16″ in thickness helped drop the fuel hose securing Adel clamp down just a hair more for clearance between the fuel hose and the NPT plug mounted in the bottom of the Superior cold air induction plenum.

I will note that I did forget about that same exact extra 1/16″ when I modeled up a new mixture cable bracket in CAD, so the cable mounting hole sits 1/16″ lower than on the other bracket. Clearly I don’t think this is going to break the bank.

After another successful round of machining I then put new desiccant in the plugs on the engine. I also “misted” (as best possible) the cylinders with preservation oil since I know it will still be at least another 2-3 months minimum before engine start.

With that I packed it in for the evening to do some research. Tomorrow I plan to focus on the GIB throttle handle: both in converting it to reverse mode and at least its initial installation.