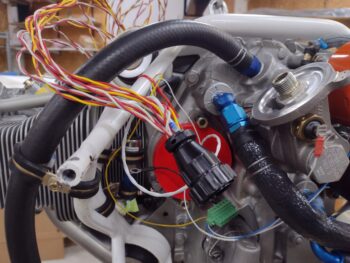

Today I met my goal of getting all the hoses installed on the front of the engine (oil cooler connections will be the last no-kidding 2 hoses).

I started off by adding fire sleeves to the oil hoses I made up yesterday. Here they are mounted on the front engine area (along with all the other hoses as well!).

To stack the deck in my favor in avoiding any leaks, I employed a little trick that I picked up from Nate Mullins: using DEL fitting seals —soft thin aluminum “caps”— in all the AN connections.

Rewinding the build tape just a bit, here’s a shot of the crankcase vent hose installed and secured… obviously with the oil filter off again to assist in both this task and the final install of the oil hose to the upper oil port.

I then took the old oil level tube (aka dipstick tube) off and spent a good little bit of time cleaning off the edge around the hole before then installing the new oil level tube. I have to say, not only does that anodized aluminum look great, but I also gain an acceptable 1/4″ clearance between the tube and the engine mount. I’d like just a skooch more, but even with a rowdy engine during startup I don’t see any damage going on here.

For my daily arts and crafts project, today I’m slowly designing what will be the plug for glassing up a cooling shroud for the engine mechanical fuel pump. The plan thus far is to have one ply BID on the inside (since carbon fiber doesn’t play as well with aluminum) with 2 plies of CF on the exterior.

Again, this will have a port that is fed via SCAT tubing from the NACA scoop on the aft end of the RAM air scoop… that serves split duty specifically for cooling this fuel pump and the PMag ignition.

That being said, I’ll dial in this design over the next few days most likely before glassing it up… this below being the 3rd iteration of the design so far. I also plan on adding to it and 3D printing a larger test piece overnight.

I’ll leave with you with a final pic of today’s work.

But first, to be specific, I’ll point out that I installed the 2 accessory oil lines from yesterday (IN/OUT), the crankcase vent hose, the oil heat oil return hose, the main fuel line on the OUT side of the fuel pump (feeds the fuel injection servo), the fuel feed line on the IN side of the fuel pump, the fuel pressure gauge hose, and the oil pressure gauge hose. In addition, last night I terminated both ends of the -8 stainless steel hose with AN fittings in prep for connecting up the oil cooler (temp connected on the outboard side of the external vernatherm). Besides the new oil level tube, I also installed the overflow port fitting on the front of the mechanical fuel pump.

This is the lion’s share of the work for the front side of the engine. Tomorrow I’ll safety wire the oil filter and the oil level tube. Besides the cooling shroud for the fuel pump, I also need to make one up (if I have the spec sheet) for the PMag. In addition, I also need to work the install and configuration of the oil heat standpipe, which I plan to do concurrently with verifying and marking the new dipstick rod.