I started out today identifying the location for the 2 CAMLOCs along the aft cowling to wing junction. Once located, I marked the spots to drill the holes.

I did this on both the left and right side, and then installed the aft 2 clecos. I then removed all the hot-glued popsicle sticks.

I then removed the bottom cowling entirely to reveal the aft 1/3 bottom cowl mounting flange off of each wing.

I pulled the peel ply and then marked and trimmed each aft side cowl mounting flange (adjacent to the popsicle sticks).

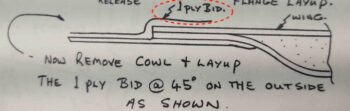

After the 5-ply BID flange is glassed in place the plans then have you glass an outside 1 ply of BID to secure the 5-ply BID layup to the wing.

To do this layup I first needed to sand a good 1″ strip along the edge of each wing root.

I then laid up a ply of BID on each side, peel plied it and then set the cowling back into place and weighed down the edges to compress the 1 ply BID layup as best possible. To be clear, I applied a strip of tape along the inside edge of the cowling side to act as a mold release.

I then double-checked the layup and left it to cure overnight.