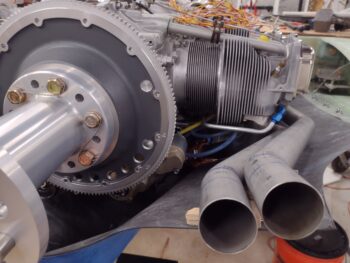

Today was all about getting the left exhaust pipes configured in situ.

I started off with the left inboard exhaust pipe and marked its cut line with the green tape.

I then made my initial cut on the left inboard exhaust pipe.

With a 1/2″ spacer in place for minimum clearance you can see the resulting gap between the 2 pipe segments.

I trimmed the forward 90° segment about 1/8″ on the bottom and about 1/4″ off the top. This trimmed 1/8″ on the bottom reduced the depth of the pipe by about 0.070″ (from the very lowest point). This gives me a minute bit more clearance with the cowling, but I’ll take every bit I can. The differential amounts removed served to angle the opening up just slightly.

The green tape is the next round of trimming for the aft segment of the left inboard exhaust pipe. You can see it will bring the joint much more closely aligned…

Although the new cut didn’t make for a perfect connection angle… I’m “walking” these joints in so as to not overshoot the required angles.

[Note the curved “dip” of the first ~2 inches of the aft pipe segment? (right after the cut) Although this rounds out the flow and makes for a nicer curve, it also drops the pipe to the closest point of all the exhaust pipes in relationship to the cowling surface… I’m thinking strongly of removing this curved section and replacing it with a straight segment of the same length]

A bit wider view on the left inboard exhaust pipe.

Although I marked the left outboard exhaust pipe cut line with tape along with the inboard pipe, I didn’t want to convolute the information flow above… in reality I cut the inboard pipe first, then the outboard pipe, before fine tuning the inboard pipe.

As I was pondering the forward curved 2-inch section of the inboard pipe I mentioned above, I cleaned up the cuts of the outboard exhaust pipe and then mounted the outboard exhaust pipe 90° section.

I then taped the left outboard pipe in place with spacers for elevation and cowling clearance. After some long pondering on this outboard pipe as well, I decided that I will most likely shape the (currently cut) weld joint to pivot the pipe in a clockwise manner (looking towards nose) to gain a bit more cowling clearance and also more clearance for the #1 cylinder spark plug (the clearance is too close for comfort at this point).

In addition, the aft end of the pipe will have to come up about a 1/4″ higher to facilitate the clearances above.

Here’s a couple shots of the “nested” left side exhaust pipes… definitely an improvement from what they were! (but we can do better….!).

And a look at the right side pipes.

Admittedly, these shots are a hair misleading because the wood spacers are both lifting the longer pipes UP while also pushing the flange of the lower cowling DOWN just a bit. In reality, these right-side pipes will both most likely need to come up about 1/4 to 3/8″. The bend, whether an actual bend or cut/reweld will be a few inches aft of the corner of cylinder #2.

And here’s one last shot of both left and right pairs of exhaust pipes in their newly elevated states. Yes, it’s a work in progress folks!

My plan is to work these exhaust pipe configurations over the weekend and have them done by next Monday/Tuesday. Then as soon as James has time, I can get these things welded up and get on with the upper cowling install.

I will note that there may be more welding required on the aft ends of the pipes if they need to be turned downwards to be leveled out on a more horizontal plane… just a thought at this point.

Pressing forward!