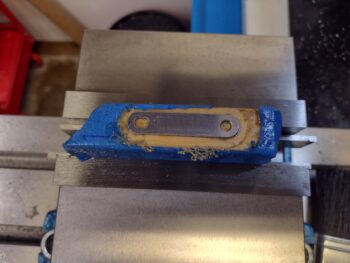

I started off today by installing a RivNut on the aft side of the GIB throttle quadrant cover and a Clickbond on the front side of it as well. I used my spreader clamp to keep the RivNut pressed into its hole fairly tightly, with the pressure transferring over to the Clickbond side as well so I didn’t need a separate clamp for it.

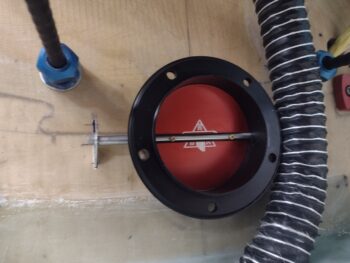

While the 2 attachment points for the GIB throttle quadrant cover cured, I then got busy machining the final aluminum 0.04″ thick version of the RAM air can butterfly valve open/close lever.

Here’s the final machined aluminum lever for the RAM air can lever. I will probably make one up out stainless steel in the not-to-distant future, but this one should do fine for right now.

After some judicious Dremel tool and hand filing work, I then installed the RAM air can butterfly valve open/close lever to the end of the RAM air can butterfly valve lever pivot rod.

I then installed just the nose piece of the RAM air can to determine where to cut the slot in the firewall for the RAM air can butterfly valve open/close lever to transit into the hell hole.

Then, using my trusty Fein saw and hacksaw blade, I carefully cut a slot into the firewall for the RAM air can butterfly valve open/close lever. Here you can see the lever down with the butterfly valve closed, and the lever up with the butterfly valve open.

With my RAM air can shenanigans completed for the day, I got back to work on the GIB throttle quadrant cover RivNut —which I simply cleaned away the excess flox— and the Clickbond, which I then prepped and laid up 2 plies of BID onto. Of course I peel plied it as well.

A few hours later I pulled the peel ply and tape and cleaned up the layup edges. Voila, initial mounting hard points for the GIB throttle quadrant cover complete!

I then set the cover back in place to simply conform it was going on without any binding or twisting.

I also mic’d up the GIB throttle handle to prep for machining to length, which I will attempt to do tomorrow. Also on the list for tomorrow is the next round of glassing on the GIB throttle cover, and the initial check and install of the RAM air can lever actuator.