Today wasn’t a big work day on the build since I had my little buddy with me a good portion of the day.

I was able to wet sand the surfaces of the white nose gear components with 350 grit sandpaper before prepping and then applying another coat of white paint. This time I used a bit more paint and what was supposed to be a higher quality foam roller, but I still ended up with a myriad of little air bubbles on the paint. Note that while a majority of boat paints need tipping with a brush, this system supposedly doesn’t require that.

The finish on these parts is not super critical since they are not located in an overly hi-vis area, so it does allow me to dial in the paint application process while I concurrently knock the painting of this stuff out. I may need to do some wet sanding and buffing out for these guys, but clearly would like to avoid that on the entire plane’s painted surfaces.

I’ll do some research and make some calls.

I understand these aren’t the greatest pics below… I actually had my little 12 yo buddy help me mix up some West 410 and fill the numerous pinholes on the bottom cowling. I originally figured I had spotted about 12 of them, but the final number was well over 20.

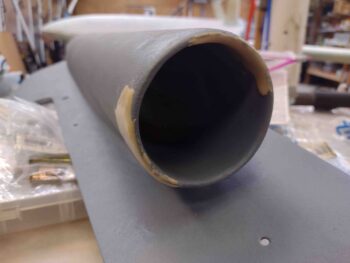

I then used the remaining bit of West 410 that was in the cup to add a little thickness to the outside of the RAM air scoop opening on one side, and then fill in a bit more on the inside of the lip about 180º out from the first fill. I’ll continue my iterative process of filling and dialing in the shape of the RAM air scoop opening to ensure it has “a pleasing shape.”

Tomorrow I plan on sanding down all the gray primered components and applying a coat of white primer to them.