I actually went flying with my buddy Clark for most of the afternoon, so I got into the shop a little late.

I started off by filling the gap between the wing and the CS spar/strake with urethane foam on each side of the plane, and then covered the foam strips with duct tape.

I should note that before I proceeded with any dam-building, pour-foaming or wing-to-strake-intersection-glassing tasks, which to be clear is all a prerequisite to mounting the upper cowling, I took a good 10 minutes each side to note, mark, measure and annotate the positions of my strake storage compartments.

I then constructed a dam for pour foam over the left CS spar using cardboard and duct tape.

After completing the dam, I whipped up some pour foam and poured it into the dam. Unfortunately, my first round of pour foam —that I stirred for about 70 seconds— was NO GOOD.

As I tested some of the foam left in the cup, I could tell it just wasn’t right… it was too crunchy and didn’t have any “spring” to it. Moreover, I could really tell it wasn’t a good batch because it came off without a whole lot of effort and merely crumbled into powder.

I tested out a small batch by stirring the old pour foam for well over 100 seconds, and that did the trick.

With my test successful (apparently old pour foam needs a bit more stirring to get the 2 parts to react correctly) I went for another attempt at getting good pour foam into the left CS spar dam.

About 20 minutes later I removed the cardboard dam to reveal a nice loaf of bread… er, uh, a nice batch of pour foam!

I’m either efficient or lazy, but for the right CS spar I re-used the dam I used on the left side by simply flipping it over and reapplying tape.

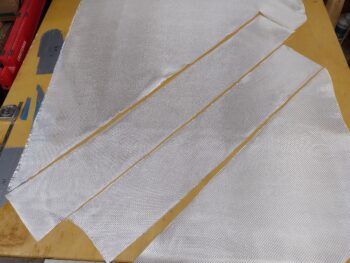

I did 3 rounds of pour foam on each side, and as I waited about 10-15 minutes each round to ensure the pour was good, I started cutting the glass for the layups I plan on doing tomorrow.

I’ll note that I’m going to kill 2 birds with one stone by not only laying up over the (shaped) pour foam area, but also bridge the gap between the wing and the CS spar/strake (after I remove the wings I’ll add more glass on both the wings and CS spar to secure each half of the transition bridge on the underside of the flanges).

Here we have the right CS spar covered with pour foam that’s contained within the dam.

After I finished cutting the glass, I then pulled the dam off the right side CS spar pour foam fill.

I then grabbed my wood saw and hacked the top off the left CS spar pour foam fill.

And then did the same thing on the right CS spar.

There was still some snack, crackle, pops going on with the foam, so I’ll let it percolate overnight and shape the pour foam applications with my sanding board tomorrow.

Moreover, it was quite late and I am ready to pack it in for the evening. I’ll continue this task in the morning.