Around the time of my last post, my old age (and previous injury) showed up as I threw my back out, majorly. I figured it would last just a few days but it was fairly severe for well over a week, and I’m just now getting comfortable doing some stuff without crazy pain.

As I was researching a new 3D printer to replace Bob, I found a couple of things that intrigued me greatly. First, was the new plethora of high-end carbon fiber filaments that can be 3D printed (on a higher end 3D printer) to create some phenomenally strong parts.

Next, was a 3D printer that could print those carbon fiber filaments in not only an enclosed unit, but way faster than what I’ve ever been able to print and with a build volume that is quite impressive. The only catch is that you have to either spend well over $10K for one of these 3D printers …. or, you can use one of the many published open source design machines that are out there. Uh, just one catch on the latter: you may be able to find one second-hand, otherwise these have to be built versus just shelling out a large chunk of cash.

One such 3D printer that I seriously had my eye on was the Voron 2.4. Although you can self source the materials to build one, there are a few different companies that sell kits with just about everything you need… except one major thing is not included: 3D printed parts.

If you’re interested, here’s a pretty good overview of the Voron 2.4:

You see, the major components (brackets, connectors, housings, etc.) of these 3D printers are ABS plastic, that you can either buy outright or print yourself. This is one reason I went with the Sovol SV-06 3D printer, because at some point IN THE FUTURE I planned on definitely building one of these beasts. And since I’m a) cheap, and b) wanted the experience, I would do my own 3D printing of the ABS parts.

“The future is now!”

Then I threw my back out. In between stretching and back exercises, I spent a good bit of time on the computer researching both Long-EZ build stuff and 3D printing stuff. I think boredom got the best of me and during my research I ran across an open box Voron 2.4 kit on Ebay selling for hundreds less than currently available elsewhere… yep, I pulled the trigger.

Here’s the unboxing and inventorying of the kit.

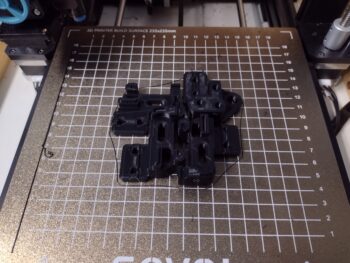

Once I pulled the trigger on the kit, I started 3D printing the ABS parts in earnest. I had “Sally” (the new printer) working just about 24/7 printing out the parts. I had a box of unopened black ABS on hand for over 6 months that I was going to test out with Bob, but never got to it. So I used it as my main color for the Voron 2.4.

My plan was to work on the Voron 2.4 3D printer until my back was better, just another few days I guessed. But this was one bugger of an injury, and I was still pretty tender for another week plus.

Since Sally was doing the major work at this point, it allowed me to recover in a decently leisurely fashion while still getting something accomplished. It really didn’t take long to assembly the parts once I had the 3D printed parts created. I would construct the parts for a bit, then take a break, do my back stretches, do more prints, more back exercises, more assembly, etc.

Here’s some more parts of the Voron 2.4 being assembled. I decided to use blue as my accent color and ordered a roll of ABS from Amazon, which I had in hand a few days later.

The Voron 2.4 uses linear rails for all the axes so it is very stable, which is obviously a requirement to allow printing at high speeds.

Just some examples of a few more black and blue 3D printed ABS parts. I have to say, although somewhat slow, Sally did a great job of printing out these parts and the enclosure on the Sovol worked a treat.

I do plan on getting back on the plane build as soon as possible, and have been doing some good research on that as well (I’ll report on all that as I come to those components during the build). In the meantime, I’ll continue to putter around like an old man and at least get this Voron 3D printer as far along as possible until I jump back on the plane.