Today I started off by heading about an hour north to help out some friends do some household repair stuff. I was there about 4 hours before returning back home, so it knocked a good half a day off my build tasks. Plus, I have to admit I was exhausted when I got home so I took a good nap.

Before I left to help my friends though, I was able to configure both USB thumb drives for my respective HXr and Mini-X EFISs. I then upgraded the software on my Mini, which is something that I haven’t done since I bought it in 2014. I also backed up the configuration of each box to its respective thumb drive in case I need to reload my specific configuration of either EFIS for whatever reason.

After my nap, I got to work doing some small layups. I had planned on doing the first one before I headed up to help my friends so that it would be curing, but didn’t get a chance to do so. It was a real simple layup: just 1 ply of BID, securing the top part of the parking brake handle mounting bracket to the left side of the nose wheel cover (NB). I used a floxed fillet as well, then I peel plied it.

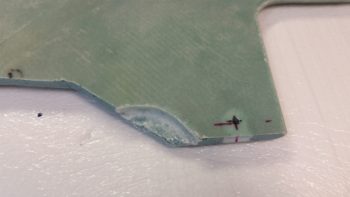

This is a number of hours later after I pulled the peel ply, razor trimmed the excess glass, and then remounted the parking brake handle assembly and cable.

Concurrent with the layup above, I also micro’d the foam, created thicker-micro’d edges and glassed in a ply of BID on the very front, top, interior corner of the left armrest. I peel plied this layup.

I also did pretty much the same thing for the heat/air duct plenum clearing notch I made in the inside of the left armrest at the bottom center of it. I did not peel ply this layup though (although when I cleaned it up after it cured it ripped some fibers loose on the edge, so maybe I SHOULD have peel plied it!).

I then spent well over 2 hours updating my electrical diagrams and printing out the freshly updated ones. I did a fairly significant overhaul on my heating systems diagram before I printed that one out as well. Tomorrow I’ll get back to it!