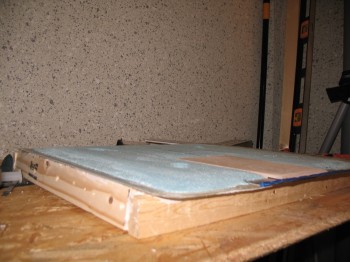

The layup over the foam landing brake looks good… all cured nicely. I cut up some of the wood strips that comes in each delivery of foam from Aircraft Spruce to make the frame that will hold the shape of the landing brake door/flap when it is removed. After I cut the pieces to length, I bondo’d them into place on the face of the landing brake and let the whole setup cure for a couple of hours.

After the bondo had cured, I carefully popped the whole landing brake/wood frame assembly off of the fuselage. These operations never occur without some damage. As Jerry “Skip” Schneider points out in his well-researched CozyPlan Unabridged Dikshunary: “Pop Off” means -Pry with crowbar and frown with dismay at the resulting holes. . . . Exactly! So that folks, is pretty much what I did.

After the bondo had cured, I carefully popped the whole landing brake/wood frame assembly off of the fuselage. These operations never occur without some damage. As Jerry “Skip” Schneider points out in his well-researched CozyPlan Unabridged Dikshunary: “Pop Off” means -Pry with crowbar and frown with dismay at the resulting holes. . . . Exactly! So that folks, is pretty much what I did.

After removing the wood spacers and cleaning up the inside of the landing brake door a bit, I marked, cut and removed the foam for LB19. I then removed the peel ply and sanded the glass to remove any offending epoxy.

After removing the wood spacers and cleaning up the inside of the landing brake door a bit, I marked, cut and removed the foam for LB19. I then removed the peel ply and sanded the glass to remove any offending epoxy.

I then cut a notch in LB19 for the hinge (LB24) and a 45°angle near and at the hinge side for clearance.

I then cut a notch in LB19 for the hinge (LB24) and a 45°angle near and at the hinge side for clearance.

I sanded the landing brake foam to shape and then taped up the hinge (LB24) loops for glassing, so no epoxy gets inside the hinge assembly.

I sanded the landing brake foam to shape and then taped up the hinge (LB24) loops for glassing, so no epoxy gets inside the hinge assembly.

I didn’t get around to sanding the glass edges of the landing brake, so I’ll knock that out tomorrow first thing.