Yes, as I mentioned in my last post, I went back to work on my Super Secret Project after Marco left after his short visit a couple of days ago. Of course not before telling Marco that I was working on a Super Secret Project… which by its name denoted that I couldn’t let him know what it was! Gotta have a little fun, right?!

Well, my Super Secret Project was simply that I ordered a 3D Printer and I was gathering as much info as possible on 3D printing before it arrived.

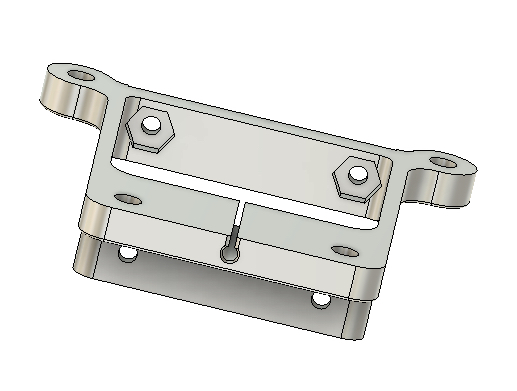

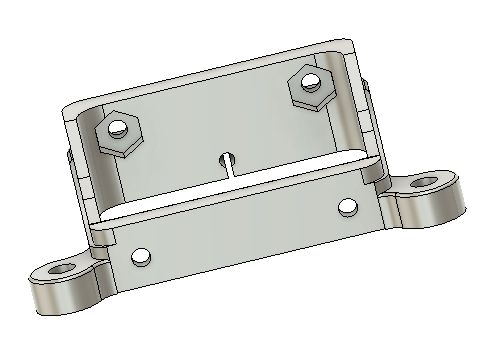

In prep for the delivery of my 3D Printer, I fired up the ‘ol Fusion 360 CAD software to convert my Starter Contactor mount from one that was designed to be machined out of aluminum to one more 3D printer plastic friendly (to be clear, I’m not using the common PLA plastic for the mount, but PETG for it’s strength and higher heat tolerance).

The main modification to the Starter Contactor mount was to add #6 nut sized hex embed notches for each screw, clearly to allow each #6 nut to be embedded into the plastic as a screw hardpoint.

Here we have an interior shot of the forward set of #6 screw/nut embed notches.

And here is a shot of the aft set.

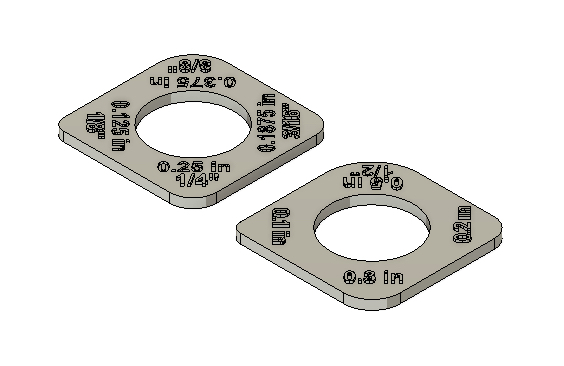

I also sketched up a set of interior corner radius gauges to confirm the corner radius’s of the Starter Contactor case.

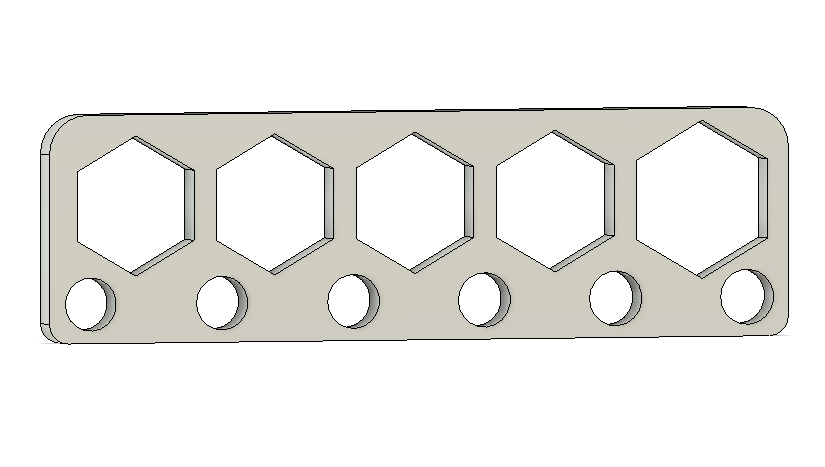

Finally, since I knew there will need to be a tad bit of extra clearance for the embedded #6 nuts and the actual #6 screws themselves, I drew up a quick gauge for that as well.

I expect to get the 3D printer later today or tomorrow, so again I’m just trying to be as prepared as possible to hit the ground running when it arrives . . . and get some 3D printing knocked out!