We’ve had some real rainy weather here for the last day and a half, which put the kibosh on cutting foam insulation or wall paneling for the workshop wall.

I decided in the same vein as my MIG welder that I would get my 3D printer back online and perhaps it could be productive while I necessarily wasn’t so much.

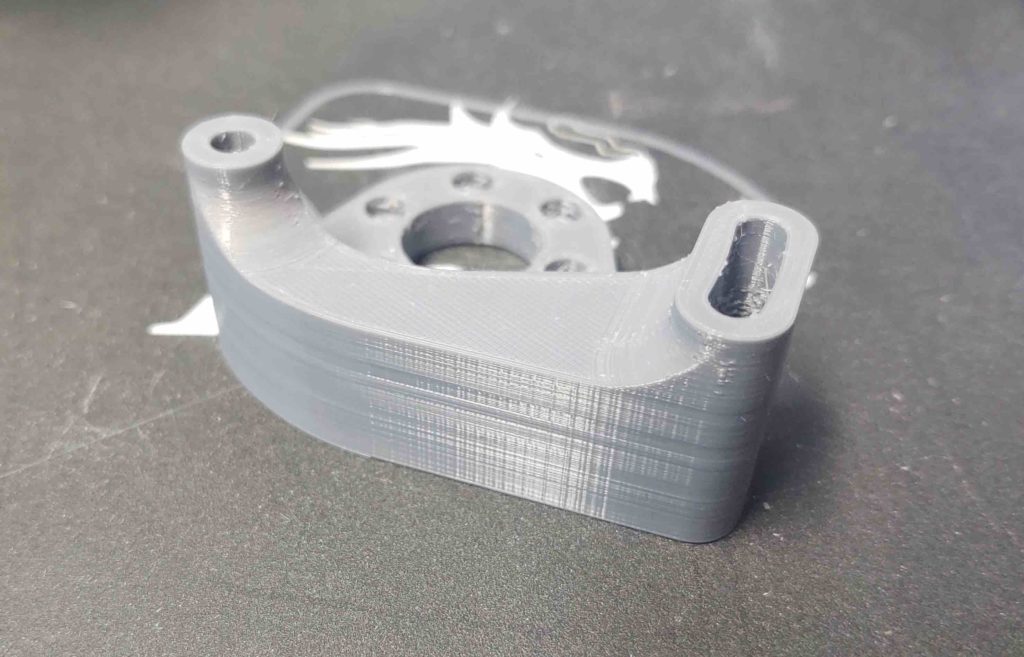

I needed to print out a mounting bracket for my lathe’s spindle RPM encoder which will be a part of a lathe upgrade that should allow the Acorn CNC software to auto-control both spindle speed and direction. This encoder mounting bracket was designed and drawn up in CAD by a guy named Franco who has a phenomenal YouTube channel on both lathe and mill CNC machining.

For higher strength than the standard/common PLA filament I used some gray PETG. This stuff is on par strength-wise with ABS, so it’s pretty darn tough.

As with my decade+ old MIG welder, I was quite pleased that after fiddling about with the 3D printer for over half an hour to get it online and all associated software programs updated, that it gave me a very decent PETG print (3.5 hours after it started).

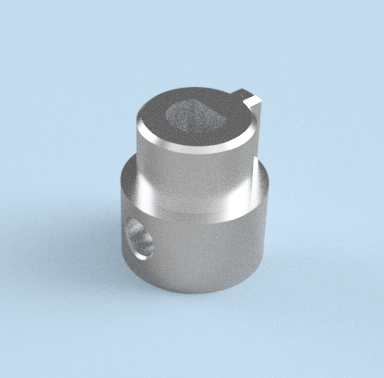

At one point Franco was selling kits for these lathe spindle encoder brackets, but has long since stopped doing so. While he had designed, modeled and shared his mounting bracket above, unfortunately he didn’t share the CAD drawing of a required key component that was included previously in his kit: the little nub that mounts to the rotating shaft of the spindle encoder and allows for attaching a 45-tooth gear to it, thus providing RPM data via a 1:1 gear setup.

So…. I then knocked off even some more rust and jumped into Fusion 360 to draw up this spindle encoder’s shaft-to-gear adapter. Here’s a rendered look at this part:

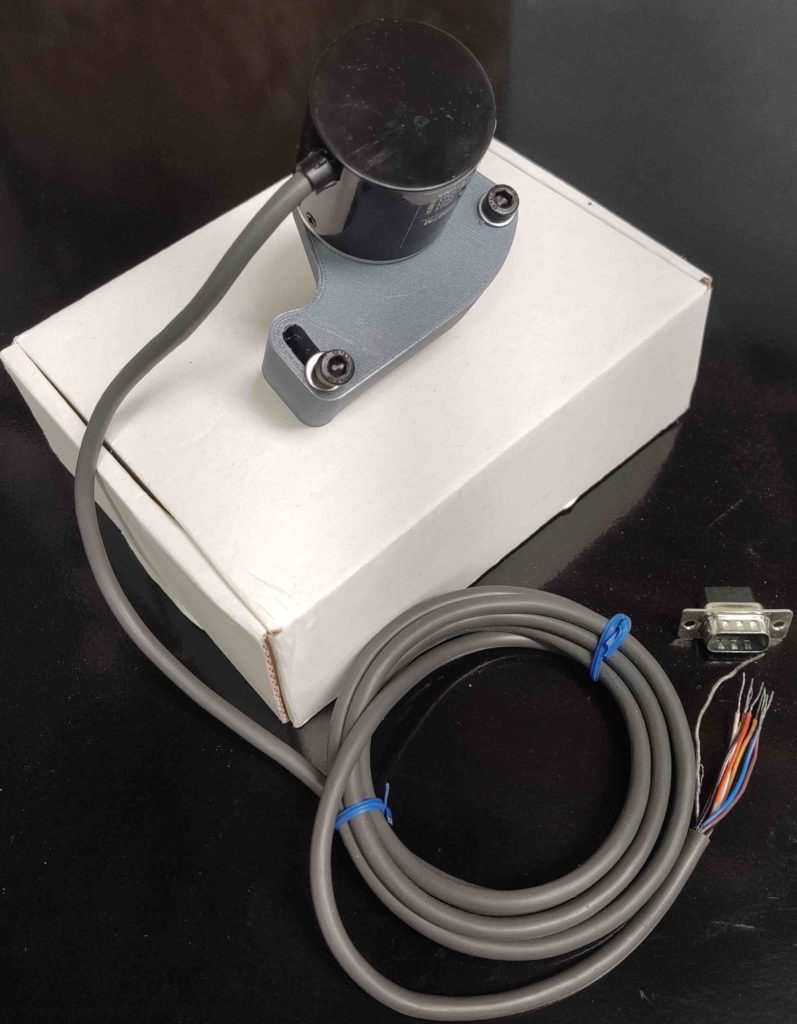

I then picked up some hardware to mount the spindle encoder to the 3D-printed mount.

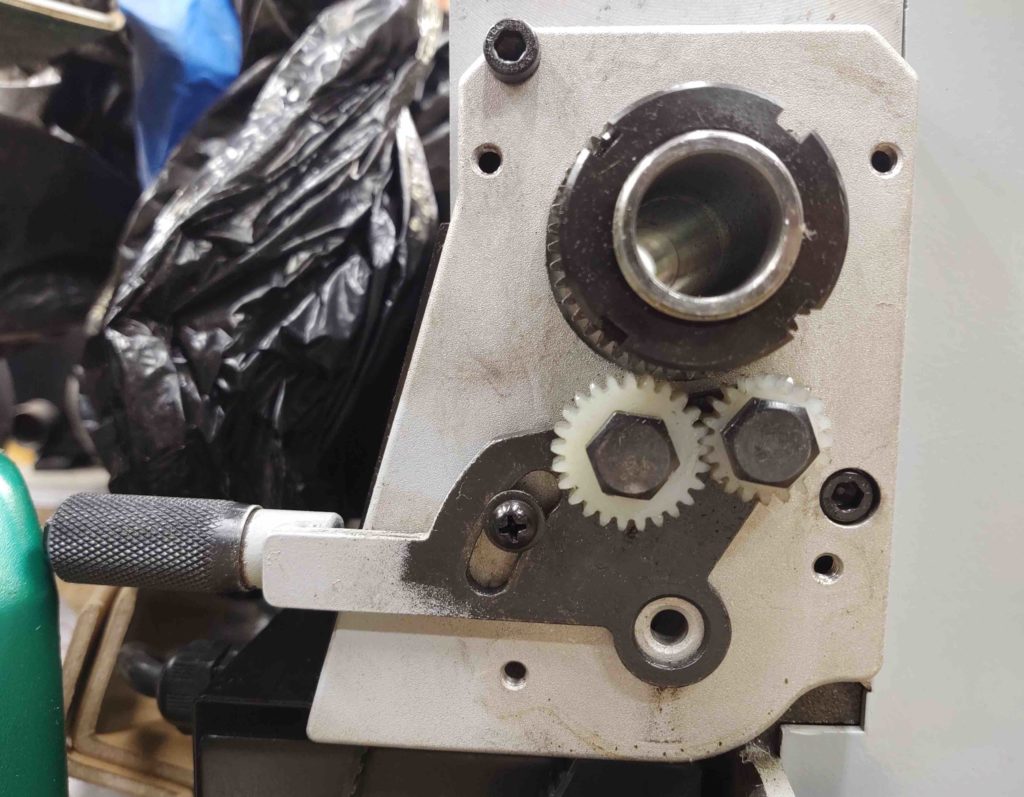

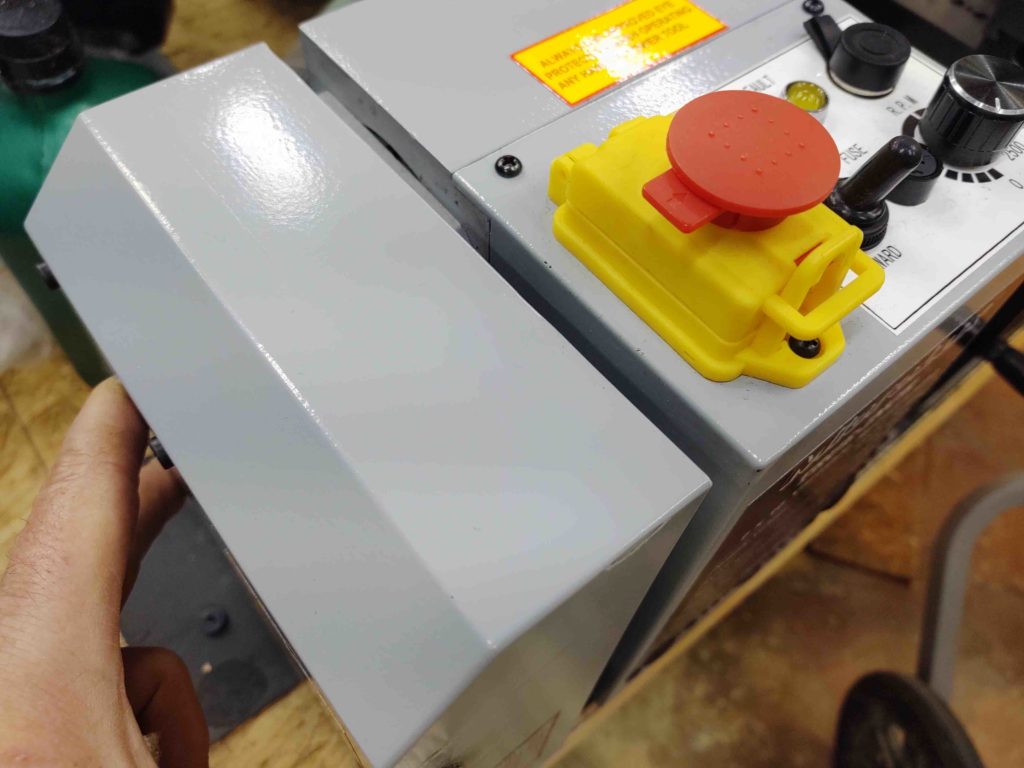

And then later on this evening I pulled the left side cover off the lathe to reveal the forward/reverse lever and associated gears that would need to be removed before mounting the spindle encoder.

Here the forward/reverse lever and gears have been removed…

And I test-fitted the spindle encoder affixed to its mount, as well as the nub and 45-tooth gear.

Below you can see a bit of the gear mounting bracket, with a M5 set screw on the side of it. PETG is notoriously stringy, and my gear mounting nub popped out of the printer with a fair amount stringiness. But it appears to be super strong.

The only negative I encountered during my test fit was that with the spindle encoder mounted I don’t have enough clearance to mount the left side headstock end cover. Essentially I’ll have to do what Franco did with his Grizzly lathe and that’s drill a hole in the cover large enough for the spindle encoder body to protrude through.

With my test fit a big thumbs up, tomorrow I’ll glue the 45-tooth gear to the mounting nub and install this thing into the lathe permanently.