Early afternoon I went to Home Depot to pick up some supplies to start the micro finish on the bottom of the canard.

Shortly after I returned home, I met future Long-EZ builder, Sohail, and showed him around my shop, and all the various pieces parts of my Long-EZ project. Of course what ensued was a long conversation on building Long-EZ’s, canards, and airplanes in general.

After Sohail left, I worked on getting the canard mounted upside down on the workbench. Thus, my first order of business was to secure the “K” mounts to the workbench surface.

I had thought about either hard-mounting the “K” mounts with screws & maybe some brackets, but I really wanted to minimize the holes in the workbench top. Plus, all but one of the “K” mounts are made of particle board and I didn’t want to add any stress to them by drilling holes, etc.

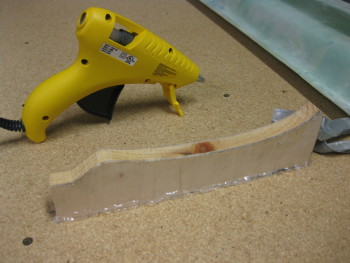

Another option was of course bondo, but I didn’t want the mess, the smell or the pain of sanding it off the workbench surface after removing the “K” mounts. As you can see by the pics, I went the hot glue route. Hot glue has plenty of strength for the job and it cleans up fairly easily.

After ensuring the “K” mounts were aligned & spaced properly, I hot glued them to the workbench top.

Hopefully tomorrow I’ll get to some micro-finishing!