I started off today by cleaning up my rather unorthodox layup for the area in-between the taxi light flanges.

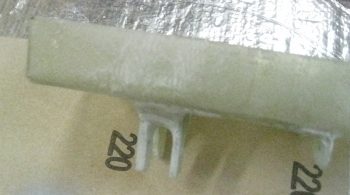

I cleaned up the taxi light mini-actuator mounting flanges.

I then drilled and mounted the battery tray mounting flanges for bracket and screw for the mini-actuator.

I then drew up the outline for the rectangular lightening hole in the battery tray. This lightening hole will also allow me to view the battery strap and manipulate its velcro tabs.

I then drilled holes in the corners of the battery tray rectangular lightening hole.

I pulled out the Fein saw and got prepared to cut . . .

I then took a quick selfie to show the FAA that I’m the one actually building this bird!

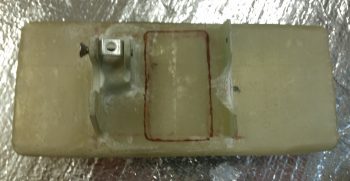

I then cut out the center rectangular lightening/viewing hole in the battery tray.

I then drilled 2 more 1″ lightening holes on each end of the battery tray.

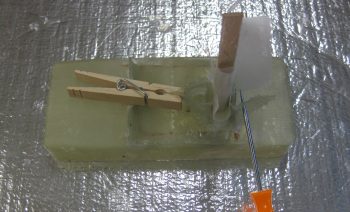

I then mounted the taxi light mini-actuator to the battery tray. Out of curiosity I weighed the entire assembly pictured below and it came out to 2.9 oz.

I then did a test fit with the whole setup in the nose battery compartment.

I had removed the taxi light cover to fill a couple of holes on the lower left side that I had mis-drilled for the mounting screws. Before I remounted it, I sanded out a small rounded half-moon shaped indention on the top aft to provide clearance for the power wires. I then decided, before remounting the taxi light cover, to go ahead and drill the vent holes on each side and the bottom/aft of the cover.

I then drilled 3 vent holes on each side.

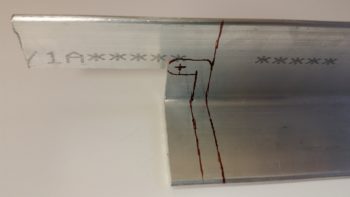

To test the initial actuator geometry that I figured out, I cut a test bracket out of a spare big piece of 6061 angle aluminum.

I don’t have any pics, but I messed around with the taxi light actuator and lever configuration for quite a while. Unfortunately, I think my initial 1″ throw estimate for my mini-actuator is about 0.4″ too short. Thus, I have to now start employing brain power –which I really was trying to avoid– to figure out how to implement some sort of mechanical trickery to turn the actuator throw from 1″ into 1.4″. I have a few ideas, but tomorrow I’m going to spend my time finalizing the finishes on the NG30 covers and tool box and let my ideas germinate a bit.