I started out today by using the Fein saw to cut off the overhanging glass from last night’s layups on the front side wheel pant pieces. I then cleaned up the aft edges where I had just removed the glass. I pulled the peel ply and cleaned up some of the peel ply strings and goobers, then I went to work on cutting the glass for the wheel pant aft side pieces (sorry, no pics of the front side pieces).

Kind of a fun point of note (at least I think so…) is that after all these years of estimating cutting BID at a 45° bias, I thought I’d do a quick check to see how I was doing. Not too shabby.

Back to work! Probably the part I was dreading the most –because it’s challenging, and I’m lazy!– is cutting and shaping the wedges to widen the wheel pant aft side pieces. It is a straight taper from 1″ at the front side to as near a razor’s edge as one can get it at the aft end. Here’s the first piece I did. Not horrible, but I did nick the front edge enough that it was just over 0.9″ vs a full 1″ thick. So I notched the front and put in pieces of unblemished urethane foam to ensure the front edge was at 1″ thick.

Below are pics of the widening wedges. The left pic is the first one I made. The right pic shows the 1″ thick urethane foam edge marked up for cutting of the major material to be removed with a hack saw blade, then the rest “fine” sanded with a 17″ sanding block with 32 grit sandpaper (note that you can see the cured layups on the wheel pant front side pieces).

Here’s the first aft side wheel pant piece widened with the urethane foam.

After I worked on the other wheel pant aft side piece a bit to let the glue harden, I then trimmed up the foam widening insert with a sanding block to match the existing sides.

I then did the same with the other wheel pant aft side piece.

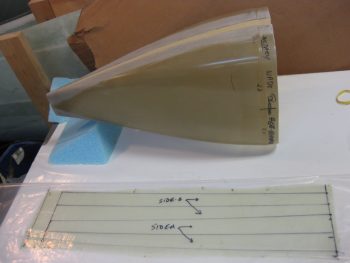

Here’s a shot of both wheel pant aft side pieces trimmed and ready for glass.

I wet out 2-plies of BID measuring 26″ x 6″ in a pre-preg setup. I then marked the cut lines on the plastic. Note that on the wheel pant aft side pieces the glass tapers into a wedge from 3″ at the front side down to 2″ at the aft vertical fin.

Here you can see the BID tapes’ taper more distinctly. The small rectangular pieces are glassed onto the front lip first, then just barely covered on the aft edge by the BID being laid up down the spine of the wheel pant aft side piece.

As I was marking up the pre-pregged BID tapes, I made sure to use a CL mark in order to have a reference when laying up the BID onto the wheel pant aft side piece. Below you can see that I’m just about to remove the top pre-preg plastic strip.

I then peel plied the BID layup on the wheel pant aft side piece. Once I was done with glassing the first side of the first wheel pant aft side piece, I then set it aside under a heat lamp and started working on the other wheel pant aft side piece. This allowed the first side to get just a little curing under its belt before laying up the opposite side of the wheel pant.

Here’s the last external widening layup on the first wheel pant aft side piece.

And here are the 2 wheel pant aft side pieces all laid up with 2-ply BID tapes for widening. This is one task I’m glad to have behind me! From here on out these widening steps should get exponentially EZ-er!

Tomorrow I’ll start off by cleaning the foam, etc. from the wheel pant front side pieces and glassing in a 1-ply BID tape. I’ll also work on trying to knock out all the preliminary steps for installing wheel pants before moving on.