I started out today by pulling the weights off the freshly floxed in place oil check door securing tube on the inside/underside of the door. Thankfully when I pulled the weights off the door, it stayed in place… nice ‘n flush with the surrounding top cowl surface.

I pulled the wire out from the securing tubes and pulled the oil check door off the cowling. Yeah, it’s not pretty, but it seems to be in the right spot to keep the door shut tightly into/onto the top cowling.

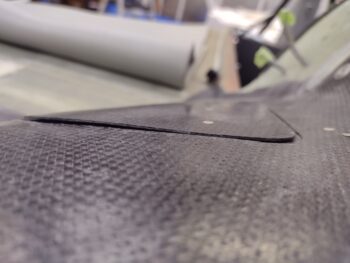

I mixed up some more epoxy, added some flox in a few key areas around the tube and then filled the remaining bigger gaps with dry micro. I cut and laid up 2 plies of carbon fiber across the tube and peel plied the layup. I set it aside to cure overnight.

I grabbed the molds I made of the forward side of the prop spinner to specifically use them as templates for cutting out the prop notches in the real spinner. Using my cardboard template I transferred the notch opening to the first spinner template (pic 1) and then cut the notch (pic 2). I’ll note, and as you can see, the templates are in 2 separate halves.

I then set the template in place around the prop blade and taped it to the flow guide.

I spent nearly 2 hours slowly dialing in the prop notch opening on this spinner template. As I suspected, transferring the opening from a flat, albeit curved, cardboard template to this template with all kinds of curves going on made for some required adjustments (thus the green tape for back filling the edge).

Getting closer… (It’s an iterative process!)

Once I got pretty darn close on the first half template, I took about 20 minutes measuring the outer diameter to get as close to 180° out on the second template as possible. I then marked up the second template and cut it out as well.

I noted these templates are of the OUTER surface of the prop spinner, so while they are great for getting the general shape and spacing of the prop blade notches configured, they are not exactly the size required. In short, I’ll be cutting the notches on the actual prop spinner a little smaller and then work through the process of widening those out in situ around the prop blades.

Overall not a bad outing, although it took way longer than I thought it would to dial in these prop blade notches. It was getting late and I wanted to hit it fresh again tomorrow as I hope to take the plunge and get the actual prop spinner notched and installed.

That being said, I got a request from my friend to take her to an appointment tomorrow down in Wilmington. This is going to wipe out the majority of my shop time tomorrow, but I’ll do what I can.

Pressing forward… or trying to at least.