Since my shop was a breezy 99° starting out, I decided it was a great temp to do some sanding! ha! I spent well over an hour wet sanding the outside longerons, the turtledeck and shoulders, the aft nose substructure, the aft nose/avionics cover front lip (just forward of the canard), and the nose hatch flange.

I then used a pencil to mark up both upper sidewalls along the fuselage and nose as a sanding guide to reveal the low spots that needed micro. After wet sanding the left side it removed the pencil marks and cleaned up the surface nicely.

The right side however still needed a bit more TLC, so I slathered up 2 decent sized swaths with micro, heavy on the West 410 compound.

I also aggressively sanded the micro on the aft end of both aft wheel pants, and throughout the remainder of the day epoxy wiped those with 4 coats (no pic).

I then turned my sights on a quick task, with the not-so-quick sub-task of finding my the 3-pin Deutsch connector kit I had ordered a couple of years ago. After 15 minutes of hunting and pecking I found it and installed a new connector half to replace the one I destroyed by drilling out the inside snap insert (still don’t why it didn’t come out as designed) on the autopilot roll servo cable.

Voila! Here we have the new autopilot roll servo cable Deutsch connector back online.

I then removed all the clamps and wood blocks off the left side CS spar “wing” and shoulder aluminum overlay that I set in place using red hi-temp RTV yesterday. It’s solidly secured in place, as is the right side, and here are the 2 completed Fiberfrax/ 6061 aluminum CS spar/shoulder heatshields in place.

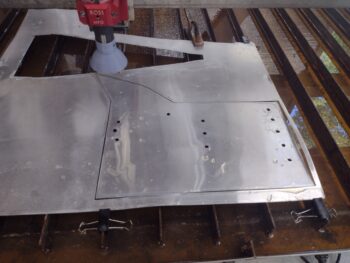

It was time to get to work on the wing root forward heat shields. After taking a bunch of measurements and assessing different mounting configurations, I decided to install (layup) a top and bottom tab at the intersection of the forward and aft heat shields, and perpendicular (90°) to the aft heat shield tabs along the edge of the wing flanges.

With both forward and aft wing root heat shields installed, the order from front to back will be aft heat shield with a thru-hole (or slot) for a mounting screw top and bottom, then the top/bottom 90° tabs also with thru-holes, and then the forward heat shield with platenut on the aft side to secure the top/bottom mounting screws installed front-to-aft.

I decided to go with 6 plies of BID for the tabs, starting on the right wing. And to create the top and bottom tabs, I simply used the taped-up front flange of the aft heat shield for the mold. I added a piece of peel ply on both top and bottom faces of the tape and wetted those out before installing the heat shield.

I then wet out two prepregged 3-ply BID layups, measuring 2.5″ high x 3″ wide, which I then simply cut in half for my 6 plies. Again, one for the top and one for the bottom.

The tricky part of course was laying these things up on the aft side of the aft heat shield flange, using a mirror and what I could see through the CAMLOC receptacles to work. I don’t expect them to be picture perfect layups, but as long as they’re structurally strong they’ll do the trick.

On the left side I decided to work the actual forward heat shield configuration and save the flange layup for first thing tomorrow (there’s a CAMLOC receptacle in the way on the bottom, so I’ll ponder a bit more on my gameplan for that).

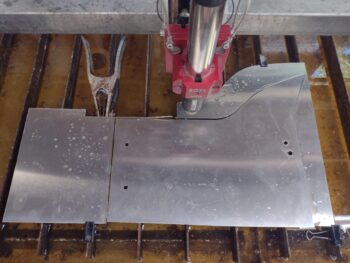

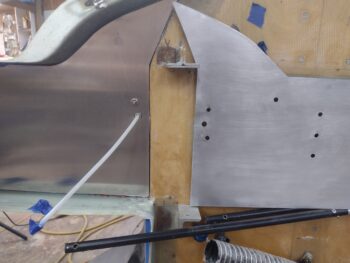

I started by installing the rudder cable conduit bracket and then inserted the rudder cable. I also connected up the aileron control tube and installed the aft heat shield.

Again, after a myriad of measurements and some trial-and-error test fits (it’s an iterative process!), I got a good working cardboard template made. Tomorrow I’ll connect up the rudder cable to the rudder and install the oil cooler to 100% ensure the rudder cable thru-hole is in the correct spot.

I then installed the left wing root aft heat shield to grab these shots of the forward heat shield cardboard mockup, which provides a pretty good idea of how the actual forward heat shield will look once installed. You can also see how the flanges of the two heat shields will sandwich the 90° mounting tabs and be secured with a mounting screw top and bottom.

Tomorrow I’ll continue working the forward wing root heat shields and hopefully get those knocked out.