Today I finally got the right side exhaust pipe brackets dialed in to a point that allowed me to re-plasma cut them out of 0.036″ 316 stainless steel.

But first, after spending another couple of hours dialing in yesterday’s scrap steel test brackets, I then traced them onto cardboard with any required corrections added in.

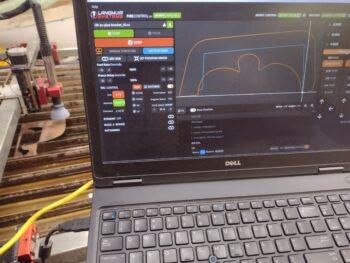

After ensuring the latest cardboard bracket mockups fit well, I then scanned them into Fusion 360 CAD and remodeled them for plasma cutting out of scrap steel, which I’m doing here:

I soaked the test brackets in white vinegar in my “parts cleaning bin” outside for a good bit to allow easy cleaning off of the rust. When I went to check on the brackets I found this cool looking butterfly sitting on the edge of the plastic container. It flew a few feet away, but I zoomed in and a grabbed a shot… something to break up the hours of working on these damn brackets!

Also while the brackets were soaking, I gathered up and cleaned up my welding helmets before performing a quick ops check on each one. My nicer, older, more expensive blue one (left) failed the ops check, and will need a new battery (I ordered an external battery holder to allow me to change it whenever I need to without having to crack open the sealed lens unit… a common hack for these helmets. Note: a lot of newer mid-price-range helmets now have easily accessible compartments on the lens assemblies for replacing batteries).

Back to the right side exhaust pipe brackets. After cleaning off the minimal dross and the surface rust, I then spent about 45 minutes doing a final dialing-in on the top steel test bracket.

And then the same for the bottom bracket.

Now an aside: Jess noticed that her linen closet ceiling either had a foot crash through it from the attic or it simply caved in on its own, so after an investigation and some measurements a few days ago I cut a sheetrock replacement for it. Jess made dinner tonight as I gathered up a bunch of my tools and the sheetrock piece to head over. I installed the new sheetrock in short order and then hung out for a few hours.

It was late when I got back to the shop, but not too late to do some plasma cutting!

Earlier I had ensured that in all the dialing-in of the brackets I did during this latest round, that none of it was additive in nature. This means that I can use the scrap steel brackets as templates for the stainless steel no-kidding real brackets, which is good since no matter how hard one tries, there is always a little too much taken off here and there when fitting the brackets in place (meaning I can start back at zero and minimize mistakes in trimming the brackets to fit).

I post processed my latest CAD files using Fusion 360’s CAM function, and then grabbed my piece of 0.036″ thick 316 stainless steel.

Here we have the second and last top right exhaust pipe bracket plasma cut out of 316 stainless steel.

And the same for the lower right exhaust pipe bracket.

As I said, it was quite late at this point so I quickly dried off the brackets and will de-dross them, clean them up and drill out the holes tomorrow. Then work the final fit for each of them.

Pressing forward!