This post covers the past few days, where my focus has been dialing in my Titanium firewall covering that will be overlaid onto Fiberfrax.

As I reported in my last post, I used an old paper template that I had made for not only the firewall size and shape, but the locations of components, pass-through holes, etc.

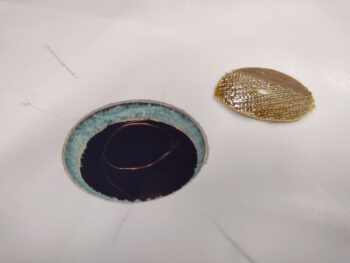

After cutting out a few points to allow me to pin the paper template to the current firewall, I then marked all the pass-through holes that would need to be made in it. I then imported the firewall template into CAD.

After getting all the pass-through points and perimeter inputted into CAD, it was now time to start the iterative process of ensuring all those holes were in the correct spot.

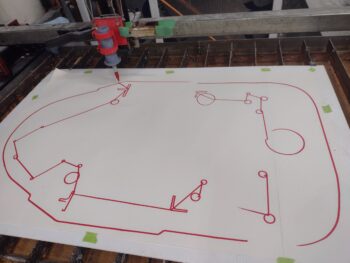

Here I’m once again using my plasma cutting table as a plotter, with a Sharpie replacing the plasma torch, for my initial firewall template.

Here’s the initial and a couple of other templates immediately after being plotted out on the plasma cutting table.

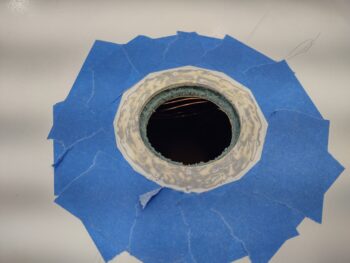

I would then spend a good half hour cutting out all the holes to allow me to attach the template to the current wood firewall to check fit and hole locations. I would then mark up the template as to which direction the holes needed moved, the perimeter lines and if any holes or alignments needed widened or narrowed.

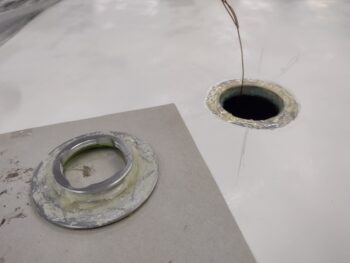

As you can see, after the initial paper template, I did this 7 more times to get the firewall dialed in. At over 2 hours work per template, that represents over 14 hours of work on these templates.

With lucky #7 needing just a few minor tweaks, my plan is to plasma cut the titanium firewall covering tomorrow.

Inching forward!