I started out today by applying primer to the outer perimeter of the inside of the landing brake. I then set the landing aside for the primer to cure.

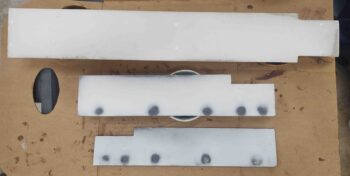

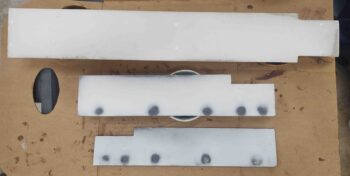

I then took the nose gear doors and the nose gear strut fairing outside and sanded down the flocro to shape.

Once I was happy with the sanded flocro shape, I then hit these components with the first of 5 epoxy wipes.

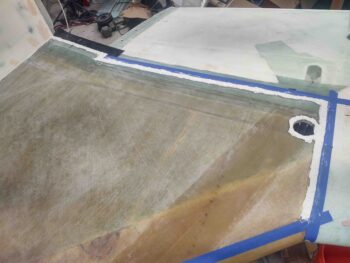

I then knocked out another task I had on my pre-fuselage flip (back upright) list, and that was to actually finish the floxing and glassing of the armpit intake scoops on the bottom engine cowling. There was about a 6″ strip of the scoop flange on each side that was secured to the cowling by flox, but not by any glass.

So I sanded down the area, added a bit more flox, laid up a ply on each, and then peel plied the layups. Voila! Here we are:

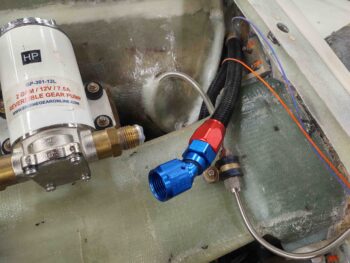

Another task I wanted to get knocked out was replacing the oil heat pump OUT hose attach fitting. As you can see in the pics below, the straight fitting was causing the hose to pull towards the front side of the fitting. Of course it’s not good to have this type of stress on a hose over time, so I ordered a 30° fitting and it came in today.

Here’s a closer up look of the oil heat pump OUT hose attach fitting.

I then dismantled the existing straight fitting.

With the resulting ragged looking hose end… usable, but not overly attractive.

I then test-fitted the new fitting to get an idea of how the hose would sit.

Since the hose is mounted inside the fuselage all nice and secure, I didn’t want to go through all the hassle of removing it just to add a fitting. Thus I bought this neat little “Koul Tool” kit that is actually made to make it easier to add hose-ends to hoses still using a vise. However, I am using it here as a funnel (which is essentially what it is) to easily get the hose end fitting onto the hose.

And Voila! Yes, the red piece looks the same as above when I dismantled the straight hose end, but this is actually part of the new 30° fitting (pic #2).

After installing the new 30° hose end fitting, I realized the hose was a tad too long and was bunching up a bit more than I wanted it to.

So I removed the fitting and trimmed about a half inch off the hose.

I then reinstalled the new hose end fitting, finagled the angle a bit and all was good. No more stress on the hose!

As a bit of prep for clearing off the nose for the coming soon sanding for micro-finish, I removed the cool nose bumper that Marco made me many moons ago.

Also, every hour or two all day I knocked out epoxy wipes on the nose gear doors and the nose gear strut fairing. Here is the last of 5 epoxy wipes, and my last task of the evening.

With the epoxy wipes done on these components, I called it a night!

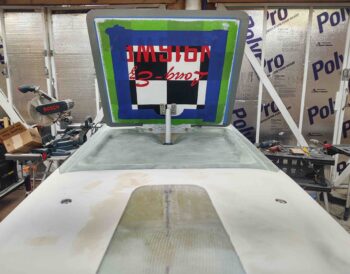

Then, after taping up the outer edge, I re-installed the landing brake onto the bottom of the fuselage.

Then, after taping up the outer edge, I re-installed the landing brake onto the bottom of the fuselage.