This morning I brought a small batch of blue paint to Phil’s shop to use on the blue paint breakthroughs around the nose hatch lip and some spots on the D-deck. After some discussion with Phil, I ended up touching up the breakthroughs on the blue paint as Phil and Ray finished up ceramic coating the white painted surfaces.

I also cleaned up and reapplied blue paint on the bottom triangular strip that ends at the bottom forward tip of the nose.

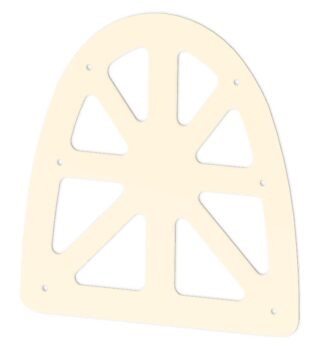

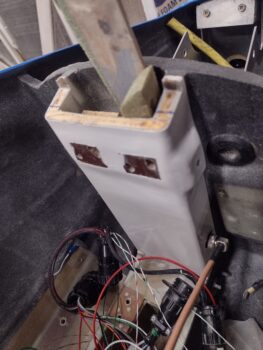

By the time I left, Phil and Ray were back to buffing out the individual parts I had left with them… here, the right rudder.

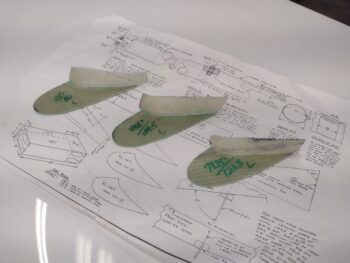

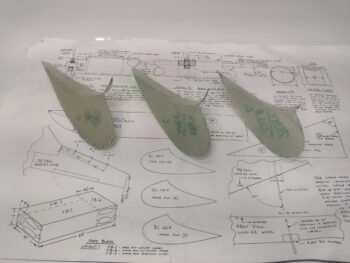

After returning to my shop, I sanded down the micro on the right vortilons to ready them for epoxy wiping, which I did next (2 coats, no pics).

I also did a final clean on the leading edge light pockets on both wings, and with some left over epoxy from the vortilons above, epoxy wiped the light lens flanges and the interior carbon fiber. This epoxy will get sanded later before the light lenses get RTV into place.

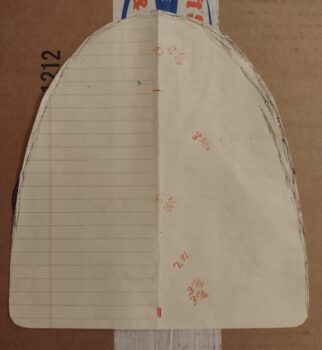

As I was working on the right wing —which I’m trying to finish up since it is next to get sanded and buffed— leading edge light compartment, I noticed that a strip of paint had been pulled up on the outboard edge. I still had the strip of LE tape I used for glassing the vortilon flanges, to reuse, and sure enough found the paint remnants on the tape.

I then sanded down the damaged paint area on the leading edge, with some minor bit more paint chipping away during the process… better now and repaired than later on when it’s flying is my opinion.

I then hit the sanded right wing leading edge paint damaged area with 2K sealer and let that flash before then applying 4 coats of white paint.

Since I was doing white paint repairs, I had about a 3″ crescent shaped area on the top of the left wing that had very visible pinholes, that just so happened to be right where I repaired the delam. Apparently I failed to inspect it closely after shooting primer, and the pinholes came through the top paint. I used a trick that Dave Berenholtz told me his painter did, which was use my finger to drive primer into pinholes to remove them.

Thus after wet sanding the area with 1200 grit, I then applied 2K sealer and used a razor blade and my fingers to fill the pinholes. Once the sealer flashed, I then applied 4 coats of paint to cover the sanded areas and pinholes. There was another spot on the inboard edge closer to the leading edge (just past lower left in pic) that had some distinct pinholes that I did the same thing.

This will all get very finely sanded by Phil and Ray before buffing out, so I expect this will be completely hidden by the finishing process and pinholes gone in the final product, or at a minimum be greatly minimized and only seen by very close scrutiny of the surface.

My last cleanup act of the evening was the black border around the blue on the very bottom edge of the left winglet (hard to get a good pic). I very carefully scraped away white paint that had intruded under the tape on the black stripe, then taped off the white and dabbed some black paint on the stripe to clean it up. Looks good and pressing forward.

More vortilon work to follow….