Today was another bust on getting some shop work in. Between business calls, meetings and knocking out some personal errands, I just couldn’t get some shop time in. One thing I could do while I was on the phone was make labels for my electrical components. So I did.

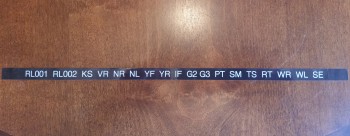

As many of you may know I designed my electrical system so that I have each component identified with a 2-digit code, and then a 3-digit identifier for the pin, wire or connector. Combine this with a 1-letter designator prefix that identifies one of 12 distinct areas of the aircraft, and I then have a resulting 6 digit code that tells me exactly where any wire is coming from or going to, and the device at each end.

So as I was on the phone I simply pulled out the label maker and started going through the list of codes.

When I got a chance I would cut a few out and label the components that I have close by. Since I was in a groove at the end of the work day, I simply rolled into digging into my stores of electrical stuff and labeling a large number of them. I would say I have about 70% of my electrical components on hand labeled.

Since I was deconflicting and updating my electrical component ID list, this segued into my figuring out more finitely each component installation location in the airplane. I pulled out the Electrical Book of All Knowledge, The AeroElectric Connection by Bob Nuckolls, and reviewed it to make sure I was not straying off the straight & narrow path of good electrical practices. Especially considering that plastic airplanes amplify a lot of commonplace negative issues that crop up in wiring any airplane.

I also reviewed a lot of other builders’ electrical systems, analyzed those, and emulated a lot of good install how-to’s. I also jotted down some crude diagrams to look at wiring runs, device locations, etc. This involved digging out a lot install manuals and verifying a fair bit of information.

By working through what I did last night, I really feel that I confirmed and elevated the completion level of my electrical system design from about 75% to about 90%, and with just a few more minor pieces of information, and perhaps a few phone calls, I’ll be really close to locking in the final locations of nearly all my electrical components.