… at least for the time being. I say this because my urge is to overhaul the configuration of my electrical components situated on the Tri-Paragon, but that will have to come later after I get this bird flying.

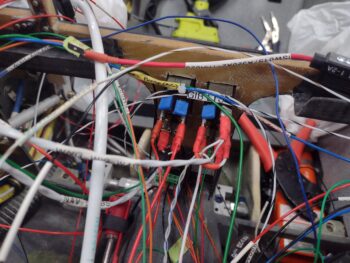

This post covers the past few days… yes, the electrical system install has been a longer, slower slog than I prefer. A lot of labeling, cross-checking and mundane work of pulling wires, soldering, terminating connectors, heat shrink, wire management, etc.

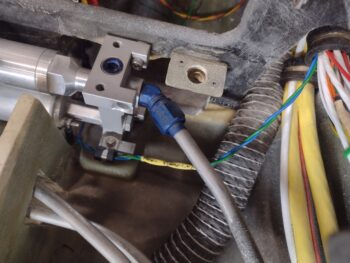

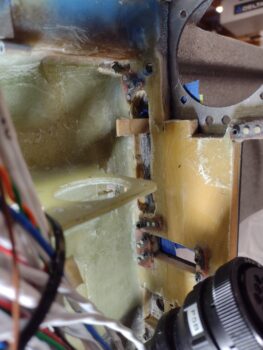

I started off today by cleaning out the mounting holes in the right side top tab on the NG-30 cover. I then installed the forward P2 connector, which would be identified as P2A, with the A designating the connector side closest to the nose.

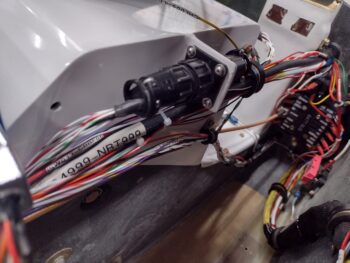

Here we have a shot of the installed P2A connector from nose looking aft (pic 1), and after I installed the P2B connector… AFTER I spent about 1.5 hours finalizing its configuration with terminating sockets on wires, labeling them and verifying the circuits with my wiring diagrams (pic 2).

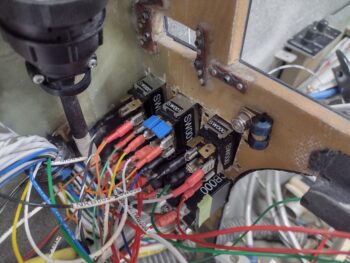

My next goal was to get the final circuit breaker installed, which is the “NAV/GPS” 5A circuit breaker for the Garmin GNS-480. Technically it was already installed and operational, just on my panel mockup in the house. Thus, some DIS-assembly was required.

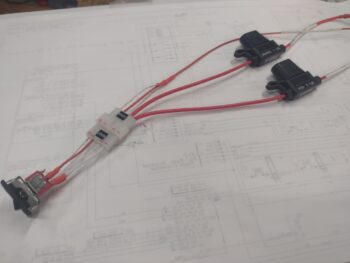

On the first lead coming off the circuit breaker I had to break open the “Deslumpifier” and pull the hot lead out of it (the one at the tip of my thumbnail).

I then had 2 more power wires to pull off the main D-sub connector that connects to the back side of the GNS-480 unit.

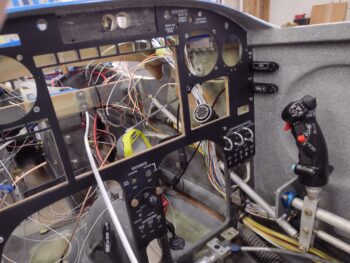

After a quick cleanup of the circuit breaker, into the bird’s panel it went. I then used a 14mm socket to do the final tightening on all the circuit breaker nuts to ensure they were securely mounted.

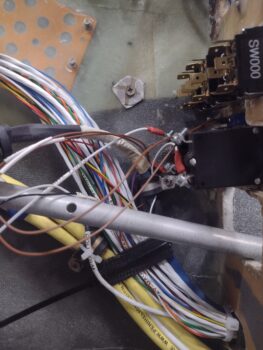

After some final “engineering” on the circuit for the StarLink Internet Antenna that will be going into the nose, I soldered up the leads of the mini-switch (sw017) and then mounted it just adjacent to the left sidewall in the lower left area of the panel.

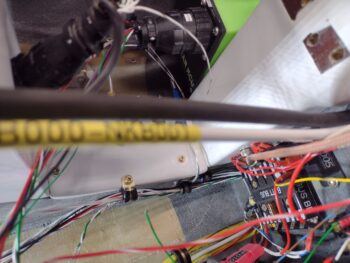

I finished off the evening doing an inventory of all the wires that started or ended in the nose battery compartment and the battery buss just on the aft side of the Napster bulkhead from those wires in the bundle from the aft side the bird, the circuit breaker cluster, or the Big 3 panel switches… all on the right side of the panel. Instead of running these wires in to the center, then forward, the back outboard, I decided to simply piggy back off the big wire bundle already transiting down the right sidewall of the nose.

The next morning, with about a half dozen wires identified, I got to work. The first wire was from the bundle and comes from the hell hole. It disconnects the TCW Tech IBBS from charging if the main alternator is offline and I’m on SD-8 backup alternator power. Obviously this terminates at the IBBS in the nose battery compartment.

The next wire was the 20 AWG black ground wire from the Master contactor (in the nose) to the Master switch. When the Master switch is flipped on this wire goes to ground, which fires up the Master contactor.

Another significant wire of note also comes from the aft end of the bird in the bundle that connects the electroair coil pack directly to the battery buss on a 10A fuse. This was one of those head scratchers with me asking, “Why did I do that?” since I ran an 18 AWG wire. In my mind I knew that the specs supported it, but later I couldn’t find them in any of my notes or emails.

The next morning I called electroair to figure out why I used an 18 AWG wire vs a 16 AWG or bigger. The tech said that the average load was less than an amp… ok, makes sense why I used the 18 AWG. He then said the initial inrush current could be as high as 5 amps. Ok, 18 AWG still plenty in my book.

BUT…

they recommended a 16 AWG wire (again, as with GRT, I’ll note this is NOT stated in the installation manual). He said if the wire was buried that 18 AWG would most likely have no issues (with Tefzel wiring, this I believe wholeheartedly). I told him I would meet him more than halfway, since I knew in my mind I could most likely get a 16 AWG wire from the nose to the area just in front of the GIB control stick. Further aft would be a MAJOR PITA and I just didn’t believe it was called for….

If this were a single seat bird I would have left the 18 AWG wire and pressed forward, but since I have that back seat I felt that I should follow electroair’s guidance as best able to optimize passenger safety by swapping what I could with 16 AWG, which was about exactly where I figured: just forward of the GIB control stick on the sidewall. This leaves about 4-5 feet of 18 AWG, which is simply not going to flinch at a 5 amp inrush current, let alone less than an amp sustained current. So final configuration is about 2/3rds 16 AWG and 1/3rd 18 AWG wire.

And that folks, is how I started the first 2 hours of Day 3: swapping out the majority of the 18 AWG wire for 16 AWG.

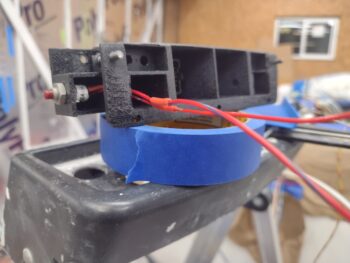

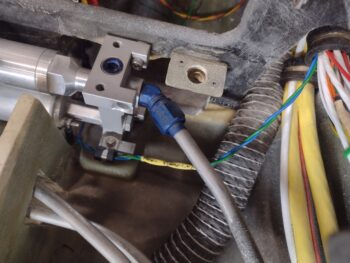

I then spent a bit of time on the EFII fuel boost pump.

For starters, I used some Simple Green and a scrubbing pad to clean it up a good bit. I then spent over an hour verifying the circuitry (which I simplified), improvising more wire labels (I burned through my wire label cartridge and the new one I ordered hasn’t been delivered yet), pulling the indicator light wire off the panel mockup to be terminated into the bundle and assessing exactly how the wire runs would go in such a tight confined space (while avoiding the sharp corners/edges of the pump).

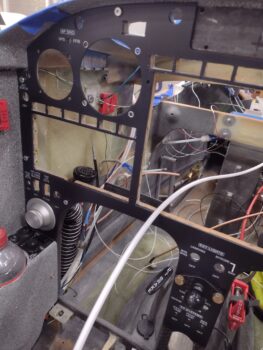

I then ran the fuel pump power wires up the right side bundle and then crossed them over to the left side switch (very bottom pic below). And with that… Voila! Both my fuel pump AND all the lower left side switches on the panel are wired up and installed.

Before I show the last panel pic, as a reminder, here is the GIB light switch control panel. As the my descriptor strongly infers: it controls ALL the lights in the GIB area.

However, my GIB (as in Gal in Back) is prone to fall asleep. And if I need those lights off for any reason, I have the Master power switch to all of them on the left sidewall just under the longeron.

With all that info in hand, here we have the Fuel Pump switch (sw009) wired up, the StarLink switch (blue) near the sidewall, and we have a green (12V+) and white/black wire at the top of the pic (GIB lights Master switch) that is now connected to the wires coming from the right-side bundle for the GIB light control switches.

Not shown is that I solder spliced the SD-8 control wire to take the IBBS charging circuit offline when the SD-8 is online. Out of 8-10 amps available when on SD-8 power, I really don’t want to be expending 2.5 of those amps recharging the backup battery (which, unless any event occurs at the very beginning of a flight, the IBBS should be fully charged anyway if/when the backup SD-8 would have to be used).

As you can see, I’m still moving from nose-going-aft to back seat forward in knocking out this wiring.

Admittedly, as I tell my wife, I’m still amazed when I work all day long and have seemingly so little to show for it at the end of the evening as I install this electrical system. It just takes a crazy amount of time to ensure everything is annotated, confirmed, verified, tested, labeled, routed and installed. But . . .

I’m still pressing forward!