The other night I was on the computer when my Spidey sense started tingling, and I started poking around eBay for throttle handles & quadrants. For some reason I was off on a mental tangent concerning my throttle handle since, if you recall, in early 2013 in response from a discussion with my buddy Marco, I found a source for some F-16 throttle handles for us. We both like the thought of HOTAS (Hands On Throttle And Stick), and an F-16 throttle handle, besides being cool, obviously offered a way of putting switches on the throttle.

Fast forward a couple of years, with both F-16 throttle & fuselage in hand, I started realizing that the Long-EZ cockpit is just not that big. Obviously, the F-16 doesn’t have a lot of real estate either, but the Long-EZ specifically has a narrow left-side console & there’s just not a lot of room for a larger throttle handle taking up a lot space in that area. In addition, the F-16 throttle handle sticks out over the pilot’s leg, which I could see getting in the way during ingress & egress to the bird.

Now, back to my foray on eBay. I was actually looking for an F-100 style throttle handle, and found a couple when I searched for “throttle quadrants.” If you haven’t seen an F-100 throttle handle, it’s rather cylindrical with just 3 buttons on the top. I was actually thinking of incorporating that style into a new design, and maybe work with Marco to build a unique one out of some lightweight 2024 aluminum. But right before I logged off eBay, I searched for “throttle handle” and found a military surplus F-15 throttle handle for sale. It was $69 and seemed to be in pretty good shape (pics below). I did some quick research & felt it was a good deal, so I pulled the trigger.

Once I received it a couple of days later, I pulled it out of the box and quickly checked the size & fit in the cockpit. The first thing that struck me was the great fit of the throttle handle in the Long-EZ’s fuselage since the throttle handle’s outboard side is completely flat vertically. This is of course because technically this is just half, or one of, the F-15’s throttle handle assembly.

Since the F-15 has two engines, this is actually the right-hand engine’s throttle handle and is located next to the left engine’s throttle handle in the F-15. If I remember correctly (I supported F-15’s years ago at Langley AFB), they are typically physically paired so they move in unison, thus their mating edges are completely flat . . . which again works perfectly in a Long-EZ!

Curiosity got the best of me so I pulled out the existing throttle quadrant and laid the new F-15 throttle handle next to it. As you can see from the pic below, the new handle is only slightly wider the existing black plastic tube handle only because of the switches mounted on the side of the F-15 throttle handle.

BTW, the cost of those aviation grade switches alone was a big factor in my thoughts on this being a great deal. Unfortunately, as you can also see in the pics, I’ll have to spend some time on cleaning up the surface of the new handle too if I want to improve its curb appeal (which I will).

Now, every once in a while when I’m off on one my quests to incorporate some unique “unauthorized” modification to my Long-EZ, and am way, way off the path of approved build actions, I actually get a break. Not just a break, a BIG break that makes something really EZ to incorporate into the design. Thus, was the case with this throttle handle.

Remember, I had originally just opened the box to ensure that what I had purchased was correct and undamaged. But after checking the size & fit in the cockpit (GOOD!) and the initial size & fit on the throttle quadrant (GOOD!), I noticed the throttle handle had 3 threaded attach points on the outboard (flat) side of the handle. These 3 points all were threaded for AN3 (3/16″) bolts, which is exactly what was used to hold the black tubular handle on the the throttle quadrant that I have (AWESOME!)

I quickly took off the existing tubular throttle handle and within mere minutes had the new F-15 throttle handle MOUNTED to the throttle quadrant. Clearly I’ll have to drill a second hole to finalize the installation, but that will be all that’s required to physically mount this throttle handle. Of course I will have to contend with routing the wiring as well, but I don’t see that as terribly difficult.

One important note on fit: you’ll notice that with the attach point of the throttle quadrant lever being located close the center of the new throttle handle, the overall space used to employ this throttle handle in the cockpit is quite negligible. It literally just adds a hair more aft of the original handle, a little over an inch to the front, and the vast difference in height between old & new is minimized by mounting the new handle “low.” Thus, there’s really only a true height increase of the throttle quadrant by about 1.5″.

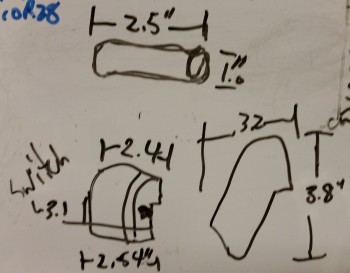

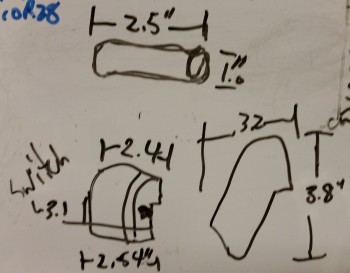

In fact, I keep a small whiteboard on the door of my shop for taking notes, listing glass cut schedules, etc. and I use it constantly throughout my build sessions. I don’t usually show my chicken scratchings on this blog, but here are the size differences I noted between the two throttle handles:

With my NEW throttle QUADRANT assembly in hand, I then checked to see how it looked & fit in the cockpit. In my opinion, it fits like a glove & is exactly what I was looking for… I couldn’t be happier!

Here’s a side view of the freshly mounted throttle handle.

And a view from front looking aft:

I snapped a few shot to show the size comparison between the old throttle handle & the new one (note the old handle resting on the new one).

And an aft view.

As you can see, the new F-15 throttle handle fits much better than my existing F-16 throttle handle (I guess I actually didn’t show the F-16 handle, so I’ll try to get a pic of that in a future blog post). It’s a little ironic, because as I mentioned before I actually worked on & supported F-15s while in the Air Force, and although I was trained on F-16s, I was never stationed where I was in direct support of them.

As you can see, the new F-15 throttle handle fits much better than my existing F-16 throttle handle (I guess I actually didn’t show the F-16 handle, so I’ll try to get a pic of that in a future blog post). It’s a little ironic, because as I mentioned before I actually worked on & supported F-15s while in the Air Force, and although I was trained on F-16s, I was never stationed where I was in direct support of them.

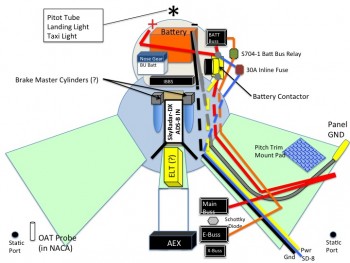

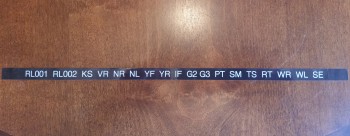

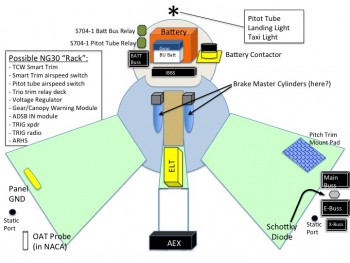

Another point in this handle blowing the F-16 handle out of the contest, is clearly this handle comes with switches mounted! That makes the task of identifying and employing switches for the landing brake, PTT, COM flip-flop, etc. much easier. Over the next week, I’ll be identifying the wiring schema for the throttle handle, and figuring out how the handle-mounted switches will be incorporated into the overall electrical system plan.

A quick clerical note, I’ll be posting this both in the Chapter 16 (Controls) & Chapter 23 (Engine) build log sections of this site (the original F-16 throttle handle posts were listed only in the engine chapter).