If you’ve been following my blog you know that I’m on a brief hiatus from building to finish up my Instrument rating. My plan is to finish up my rating by mid-March, at which point I plan on getting back to the build hot ‘n heavy. Who knows?! Maybe I’ll even finish up installing those wheel pants! ha!

One reality that I had to accept as I was preparing for an upcoming Instrument flying stage check was my lack of understanding of the Garmin GNS430 GPS navigator, which is installed in all the Cessna 172s that I fly for training. I had resisted in really getting deep in learning the GNS430 since for my Long-EZ, my plan was to install an Avidyne IFD 440/5×0 GPS. But alas, with a couple of stage checks and my FAA check ride looming on the near horizon, I realized that I really needed to nug out some training on the GNS430. This decision was made easier in part when I received an email from the ubiquitous King’s offering a 20% discount on any of their training courses. So I pulled the trigger and bought the King GNS430/530 training course (which is pretty good by the way).

As I was just getting into the 430 training, I was thinking I would buy a 430W to install in the Long-EZ since I use it so much in my training airplanes. With the completion of my Commercial rating still looming on the horizon, I would still require a lot of time behind the 430. Since the Avidyne IFD440 is a slide-in replacement for the Garmin GNS430W, why not use the 430 now and simply replace it with the IFD440 later? Sounded like a good plan. For clarity, I discussed this at length with Marco who agreed with the merits of my logic (although being a big Iron driver, he’s not a big fan of the 430).

Although it wasn’t my intention initially, as I dug deeper and deeper into learning the GNS430, curiosity of how its features compared to other units got the best of me. So during breaks in training I would sneak in quick peeks at the Avidyne and GNS480 features. As I would Google certain features that I wanted more info on regarding the 430 (holds, OBS, airways, etc.) I kept coming across overwhelmingly positive reviews on those features for the GNS480 [Admittedly from those bubbas flying behind them… to the guys that hadn’t flown the 480s, the report was that the learning curve was ‘too steep,’ the interface ‘too FMS-like,’ and a constant projected fear of no further Garmin support on these units].

As my curiosity deepened, before bed one night I spent a good 45 minutes watching a video specifically on the GNS480 operations. I was deeply impressed with the power & capability of the GNS480, and every chance I got I would spend a few minutes here and there researching it more. After a day or so of this, I sent the 480 video to Marco with a good hunch that he’d really like this unit as well (he did!).

If you’ve ever gotten a feel for my modus operandi, it will probably not surprise you that I was already communicating with a number GNS430W sellers in line with my latest 430W plan. However, there was an oddity playing out during my short-lived quest to acquire a 430W. First, nearly every seller of every 430W unit that I engaged with turned out to be a scammer. Moreover, I spent a good week working a promising deal that in the end turned out to be yet another scam.

However, I guess all things work out for a reason, because during the week I was working the potential 430W purchase with what turned out to be yet another scammer (NOTE: nearly every 430W listed on Barnstormers and other sites turned out to be a scam), I was concurrently learning more and more of the GNS480’s capabilities. Remember, during the majority of this time I was practicing instrument approaches and studying IFR flying. Truth be told, this training was probably the tipping point in my choosing the GNS480 over the GNS430W. Why? Well, as I re-flew my recent actual IFR flights and approaches on the respective 480 and 430 simulators side-by-side, the GNS480 clearly had superior capabilities when it came to flying IFR flights and approaches (in my opinion). [I’ll expound on the specific comparisons in a later post].

To be clear, with the great price (but not unrealistically low) that I would have paid for the GNS430W that I was dealing on, I would still have gladly bought it and installed it. My requirements goal here was to install a lower cost WAAS GPS unit that allowed me to fly my Long-EZ IFR. Nonetheless, by the time I determined that the 430W seller that I was dealing with was a scammer, I reset my search primarily on finding a quality, well-priced GNS480 unit. Well, in short order I was able to serendipitously do just that, finding a local GNS480 seller (and experienced pilot) that had a unit for sale.

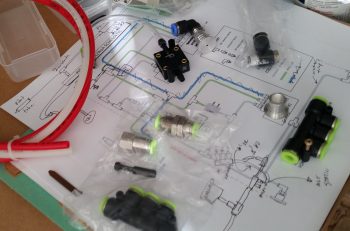

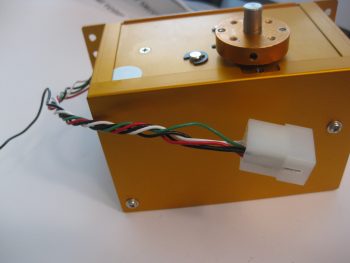

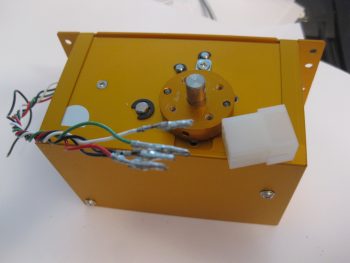

I met with the seller, Phil, at a local airport where I was able to play around with the unit in its Commander docking station. The fact that Phil was selling an entire Plug-n-play package was the deciding factor in why I pulled the trigger on this unit. Here are all the components that were included:

- Garmin checked & software updated to Vers. 2.4 and 5.1 (allows ADS-B+ out)

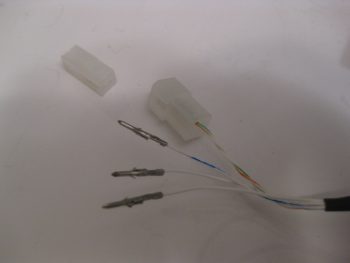

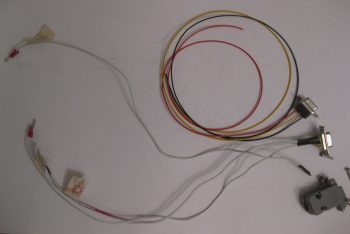

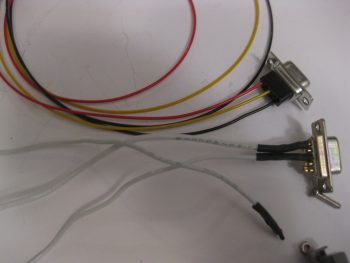

- Mounting tray (“tube”), backplate and electrical & coax connectors

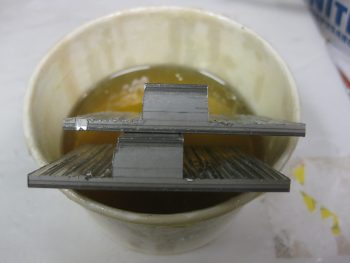

- GA 35 WAAS GPS antenna

- Data card reader + 2 data cards

- Lone Star Commander docking station

A result of my evaluation, and subsequent purchase, of the GNS480 has brought me to the conclusion that this will be the final and only GPS unit that I plan on installing in my Long-EZ. Clearly this means that my proposed Avidyne upgrade is simply off the table now. With the GNS480’s handling of voice and nav comms, its inherent WAAS GPS/VOR/LOC/ILS capabilities, and its fantastic handling of airways, I am more than thrilled to have made my decision final in identifying this GNS480 as Long-EZ N916WP’s long term GPS navigator unit.