One good thing about not getting this plane built on schedule is that it allows for me to implement really good upgrade mods that would normally mean downtime & increased complexity on a flying bird. In other words, I can take just a scant bit of extra time and roll these new mods into the build plan in whatever area before I ever start in that specific endeavor. Two such mods that I’ll discuss below are the electric nose gear system and the heating system.

First off, I finally did a bit of research and decided on the style of latch I wanted for my oil dipstick access door on my cowling. I like the way the one below operates so I picked one up from a guy off of Ebay. For those curious it’s a Hartwell H2868-1. I like this specific version since most of the ones that are this style simply have a large square plate with a hole in each corner for mounting. With the wings of this “H” style it will allow me to bend those just a hair to match any curvature I may have on the oil dipstick access door, which in turn, matches the curvature of the upper engine cowling. In addition, the main reason I wanted a latch-for-the-hatch is to preclude the complexity and pain of having to use a screwdriver to undo any number of CamLocs just to check the oil! Plus, as with everything we do, I simply think it looks cool… ha!

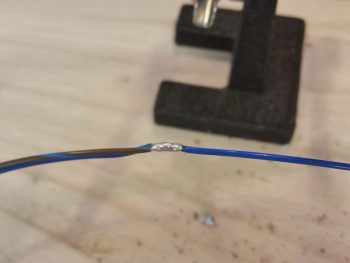

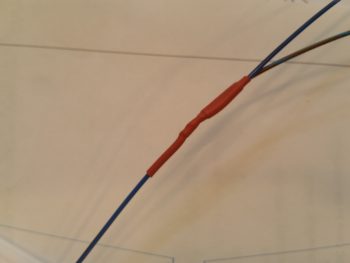

I don’t normally include this type of stuff on my blog, but since the use of my laptop DIRECTLY impacts my airplane building I thought I’d make an exception this time. So my MacBook cord finally gave up the ghost. No worries, I’ll just pop down to the store sez me to myself and pick up another one . . . how expensive can they be? Well!!! $78 is how expensive they can be. Sorry, not gonna happen. Thus, I fired up the soldering iron and soldered what few molecules of the outer shielding I could find, built a bit of a solder bridge (that’s always fun!) and slapped some heat shrink on it. And Voila! Works like a champ!

Now, back to real business.

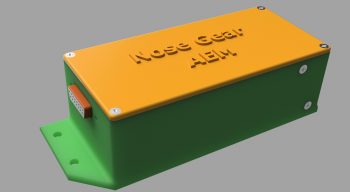

My build buddies apparently understand that I like bright shiny objects and will take off after them with aplomb if any catch my fancy. Well, Dave Berenholtz from OZ obviously understands this too well and sent an email asking me if I was aware of what Marc Zeitlin was cooking up in his evil lair. Apparently Marc was dissatisfied with the standard operations of the Automatic Extension (AEX) feature of Jack Wilhelmson’s EZNoseLift electric nose gear system. The AEX simply provides an automatic feature of retracting the nose gear after takeoff once the airspeed is above 90 knots, and conversely, will extend the nose gear if the airspeed is less than 90 knots. Short and sweet.

Well, Marc undertook about a year-long project to refine the AEX system, not just for Jack’s system, but any aircraft actuator-centric system (I’ll note for clarity that in Marc’s quest, apparently the “X” got lopped off the end of “AEX” and now it’s just the AE system). IMO, Marc’s system is fantastic in that by adding another airspeed switch, a throttle “microswitch,” and a laser altimeter, it provides a comprehensive set of parameters that must all be true for the Auto Extend to activate and deploy the nose landing gear:

1: Throttle less than 10% open

2. Speed greater than 40 knots (user programmable)

3. Speed less than 90 knots (user programmable)

4. Altitude at or below 350 ft. AGL

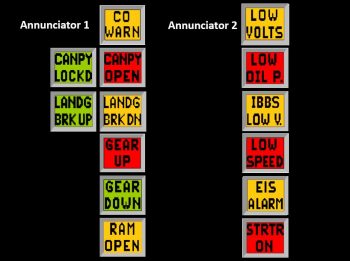

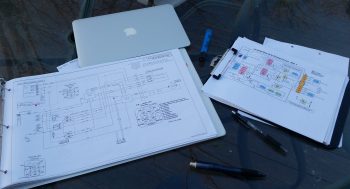

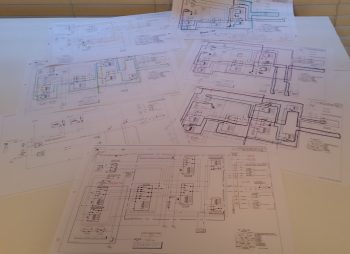

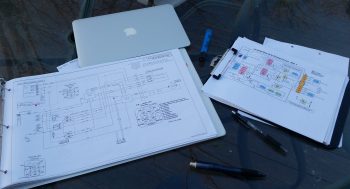

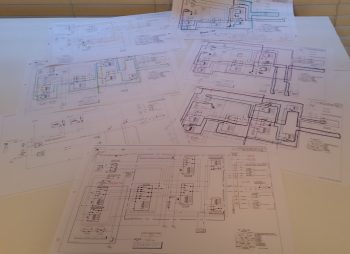

Ok! Wow, this is truly fantastic news for us Canardians! I printed out Marc’s description of the system and the electrical diagram and got to work since I wanted to assess how this would integrate into my system.

Initially, this all seemed too good to be true! Where was the catch? Well, as always seems to be the case there were two specific problems with this new system: the first in relation to my build and the other, a general operational requirement that I desired, which was offered in Jack’s original system but removed in Marc’s modification.

First, the operational requirement: Marc’s version offers no backup battery capability since Marc personally uses the ratchet drive backup system to extend the gear in case of an electrical failure. Jack sells his EZNoseLift systems with the option of the mechanical ratchet drive backup -OR- a small 1.2A backup battery that will lower the gear sans ship’s power if the electrical system fails. Hmmm…. Since I have the backup battery, this was not a good thing in regards to my system.

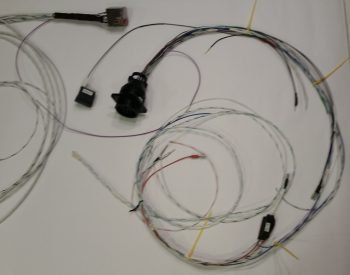

Next, as for the integration into my build? Marc’s version requires a 3PDT switch to control the gear up & down. My already terminated and installed throttle-mounted SPDT nose gear switch is in the “done” column and is perfect for driving Jack’s EZNoseLift system. Moreover, since this is an F-15 throttle handle, how this rare switch is mounted and its metal hat switch form factor make it very difficult to just pull, plug and replace with another switch. Moreover, I really have to say that I love my throttle handle just the way I’ve now configured it! On the pic of my throttle handle below you can see (mid-side handle) the stepped-hat nose gear up/down switch.

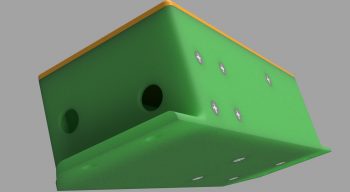

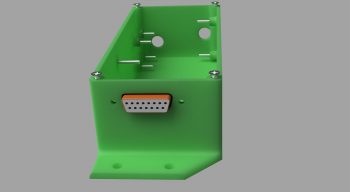

Also, one thing was clear as I stared down this road of integrating the new parts of Marc’s upgraded system while keeping the best part of Jack’s current system, and that was I really needed to truly understand and have comprehensive knowledge of how both these systems worked. To be honest, with so many versions of Jack’s system out there, I wasn’t even sure what my switch panel looked like! I went down to the shop and snapped a pic of the switch panel face . . .

. . . and the actual wiring of the switches on the backside of the panel in order to identify the correct switches and wiring circuits.

After pondering my gear switch issue for about a day, out of the blue I had a Eureka moment: Duh! just swap out Marc’s required 3PDT switch with a 3PDT relay… right? Problem solved. Uh, but wait a minute sports fans. With this being a CANARD gear switch, a problem is presented in simply swapping a switch out with a relay since there’s that pesky “-OFF-” position on our gear switch that doesn’t translate over to a “middle position” between N.O. and N.C. on a relay. Obviously, on canards we don’t simply use a binary, all-the-way up or down gear position (except for TOs/landings), but use the gear switch to position the nose in a myriad of heights off the ground when parked. Thus, my requirement was to be able to hit the nose gear up/down position, have it run up/down for a few seconds and then move the switch to the “OFF” position to stop the gear from moving any forward. Again, with most aircraft you simply have an up or down gear position, but we Canardians apparently like to be eccentric!

I was at the juncture of simply knowing that I wanted to replace Marc’s required 3PDT switch with a relay that I could then subsequently control with my throttle mounted SPDT switch. But how? Not smart enough in the ways of electrons, I posted my dilemma onto the AeroElectric Connection forum. Within an hour Charlie England started off his response with a question that gave me my answer: “How about 2 separate 3 pole relays?” Yes, one relay would control up and the other down. When my throttle-mounted switch was in the middle OFF position, neither relay would be powered on to do any action so the system would be “at rest” . . . or OFF. I had found my middle position!

[Just as a point of note, since Marc’s 3PDT switch positions were wired to create 2-N.C. states and 1-N.O. state in the up position, and opposite in the down position, it allowed me in the end to only need one DPDT relay and one SPDT relay to replace the 3PDT switch.]

With the switch issue taken care of, now it was time to tackle probably the biggest electrical challenge I’ve ever faced. I had asked Marc & Jack, et al, on the Cozy forum if there was a way to wire back in the 1.2A backup battery into Marc’s design to provide a means of getting the gear down if a total electrical failure were to happen. I had some back and forth on a type-of-relay question I had, but nothing on the backup battery except an expressed desire by some to see that “put back into the system.” With no real response, and having one solved problem (the new AEX system) creating a new problem (no backup emergency gear extend feature), I figured it was time for the proverbial: “Well, if’n you want somethin’ done yer gonna hafta do it yurself!” (Said in Ken Curtis’ Festus voice from “Gunsmoke”).

I spent a day and a half deconstructing both Marc and Jack’s respective systems, and then ala “Tony Stark” (without the flare, billions of dollars, Hollywood CGI or Jarvis) I melded the backup battery feature from Jack’s system into Marc’s new design. Thus, after chasing imaginary electrons around on paper over a couple of days I was finally able to meld the backup battery and emergency gear extension feature back into this promising new & improved system!

After verifying that my new combined design worked, I then cleaned off all my specific extraneous system info to then submit a generic copy onto the Cozy forum. I received word back from Marc Zeitlin that it would work as per my (actually his & Jack’s) design, with a number of “why-didn’t-you-use-this-component-vs-that-one” type questions, which is great since that’s how system designs are optimized. So now I have some system design “homework” from Marc that I will attempt to iron out.

Regardless, doing nothing else from this point on (besides buy all the required components!) results in a new baseline electric nose gear system that provides a very usable AEX system and allows me to incorporate the backup battery feature/emergency gear extend feature.

If you’re curious, here’s a final thought on reasons I chose the battery backup system vs. the mechanical ratchet wrench backup gear deployment system: the battery weighs considerably less, takes up no panel space as does the mechanical unit, and most importantly –for me– if I’m working any non-standard issue while in the process of landing, I don’t want to be messing around with a ratchet (which itself weighs as much as the small backup battery) and spending time getting the gear down when the flick of a switch will do it for me. Finally, a very important thing to consider that I learned while flying in Marco’s Long-EZ is that IF YOU DROP SOMETHING on the floor, it is no longer something of use to you! And unless you tie off that ratchet handle, it may end up being nothing more than added weight in your airplane while you WISH you had a means to get your nose gear down [just saying . . . IMO!]

Now, on to my final topic of this LONG post.

I had a good discussion with both Buly Aliev and Nick Ugolini regarding the integration of Buly’s oil heater system pump and system design. I have lots to think about still on this system, but one thing I did take away from my discussion with Nick is the heat output is best realized by controlling the speed that the oil pump is pumping in hot oil into the system. Thus, in able to control the speed of the oil pump, one method utilizes a PWM controller switch, so that’s just what I picked up. I can now say, “Behold, the oil pump and its PWM controller switch!” (not that I will necessarily, but I can if I want . . . !)

That’s all for now folks!