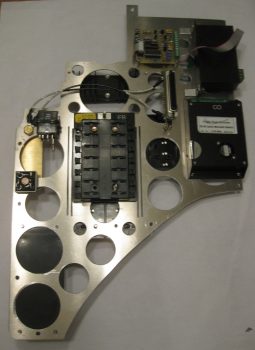

First off, as you can see I’ve settled on the acronym PQD, Panel Quick Disconnect, to describe the connectors and bracket that I’ll be employing to make the task of removing the instrument panel infinitely EZier than without this configuration. Although there will be some wires & components that will not be disconnected, either through their location just off the upper main Aluminum panel face, or because their wiring is not conducive to being split by a mid-point connector (eg Avidyne IFD COM plug P1002 & Dynon intercom wiring harness).

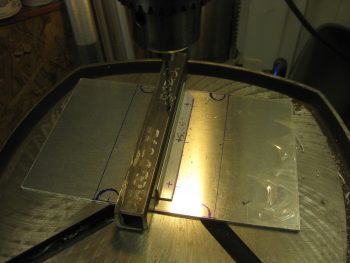

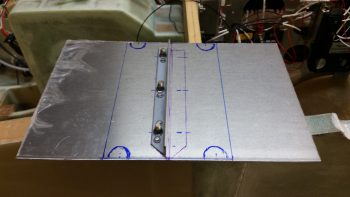

Speaking of the “upper main Aluminum panel face,” after some impromptu research I’ve decided that since I’m keeping a very large portion of the original panel in tact for strength behind the Aluminum panel face, that I’ll be using 0.063″ 2024T3 for the instrument panel. I was actually in the process of ordering that panel from ACS, when I double checked my spreadsheet and lo & behold, I had a spare 2′ x 2′ panel on hand from years ago. Woo-hoo!

Ok, back to the PQD. I had originally ordered a 1/8″ thick 2-1/2″ x 2-1/2″ angled piece of 2024 from McMaster-Carr quite a while ago thinking that I would hang a bunch of stuff off these cross shelf overhangs in the same fashion that I’m doing now with the clearly much smaller sized 1″ x 1″ angled aluminum overhangs. This angled aluminum extrusion was just too big & heavy to use in any reasonable quantity, plus as my Triparagon design matured I just didn’t have a need for it. So into the massive spare pile of aluminum it went.

Then when I was finally hit between the eyes seeing Paul Dye’s panel on the VAF forum as I was trolling for pitot-static info, I finalized my decision to make my panel fully & EZily removable. So I had to get serious on both the quantity & type of connectors to use and where they would reside. I had had a nascent thought all along of a drop down bracket on the aft right corner of the Triparagon cross shelf IF I did the fully removable panel mod. Well again, it was time to get really serious so out came the big gun: the 1/8″ thick 2-1/2″ x 2-1/2″ angled 2024. If you remember I posted a few days ago, over the Thanksgiving holiday, a mockup of my connectors on the end of this massive 2′ long piece of aluminum. With my electrical connections confirmed, and with the only mod to the actual connectors being that I swapped out the 19-pin AMP CPC connector for a higher capacity 24-pin connector (same diameter), I was ready to install the J3, J4 & P6 connectors into the PQD bracket, and of course make the PQD bracket itself.

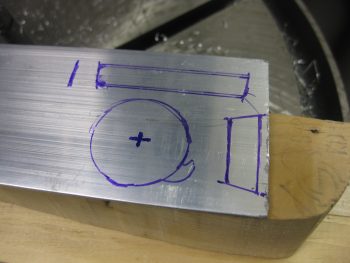

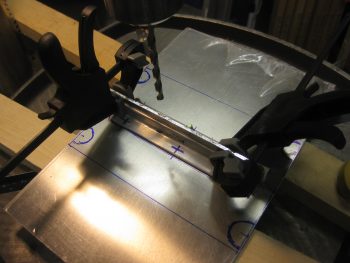

I started by marking the connector outlines on the angled extrusion.

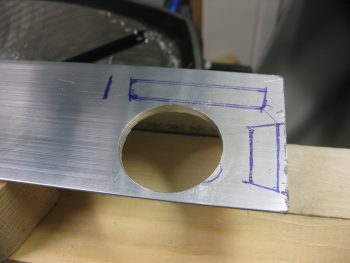

I then used a hole saw to drill the 1-1/2″ diameter hole for the P6 AMP CPC connector.

Of course I had to check the fit…. looking good so far!

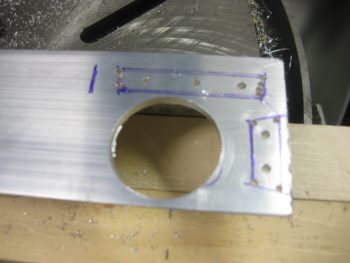

Then came the odd shaped 37-pin & 15-pin D-Sub connectors. I figured this would be a total hand-jam custom build process (“custom” means it works fine, but it ain’t always pretty!). I drilled some small starter holes, focusing especially on the corners.

I then expanded out the center area holes with a large diameter drill bit, which is the same diameter as the width of the D-Sub connectors.

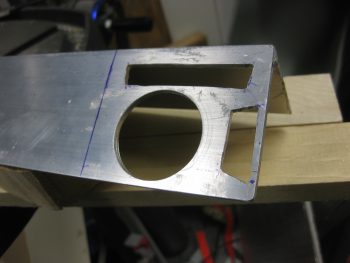

I then employed my jig saw –and a few expletives!– to finalize the cutouts for the D-Sub connectors. Here’s a shot of the initial rough connector cutouts in the beginnings of the PQD bracket.

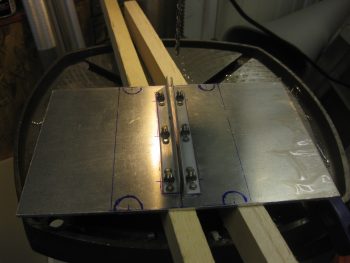

And another shot after I cut the bracket out of the angled 2024 extrusion (it was raining so I plunged forward using my Skil saw to cut the bracket out!).

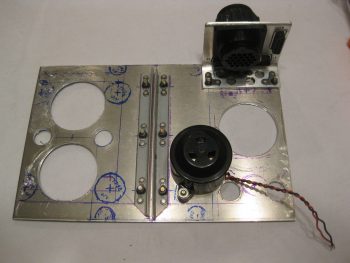

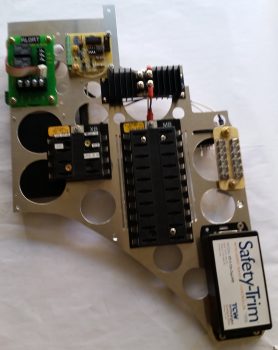

I then test fitted the connectors in the PQD bracket.

Here’s a shot of the backside of the connectors test mounted into the PQD bracket.

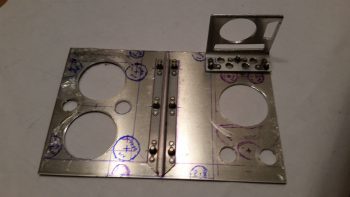

I then took the PQD bracket upstairs and mocked it up on my Triparagon cross shelf. After finalizing the mounting location for the PQD bracket on the cross shelf, I then digressed a bit from the PQD bracket and figured out where my first round of lightening holes would go on the cross shelf.

I took the cross shelf and the PQD bracket down to the shop and proceeded to drill the mounting holes for the bracket into the bracket tab and the cross shelf. I then added 3 K1000-8 nutplates to the PQD bracket mounting tab. As you can see, I also drilled 4 lightening holes in to bracket’s mounting tab.

Here’s a view of the top of the PQD bracket mounting tab, with the flush rivets of the 3 K1000-3 nutplates visible.

I then diverged from working on the PQD bracket for a bit and drilled out the first round of a bunch of lightening holes into the Triparagon cross shelf. After finishing round one of lightening holes, I then went back to work on the PQD bracket and drilled countersinks for each of the 3 -8 screws into the top of the Triparagon cross shelf (shown 2 pics below). I then mounted the PQD bracket to the cross shelf.

I then test fit the cross shelf back onto the vertical Triparagon plate. Note the 3 countersunk -8 screws securing the PQD bracket into place. (Note: while I was drilling the PQD bracket mounting holes through the mounting bracket into the cross shelf, the bracket misaligned slightly. Nothing earth shattering, but definitely a slightly-sloppy mounting AND a loss of cool points!)

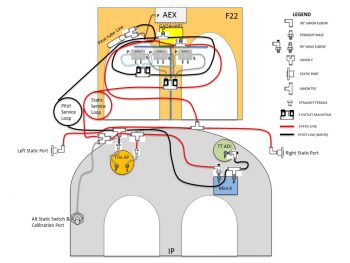

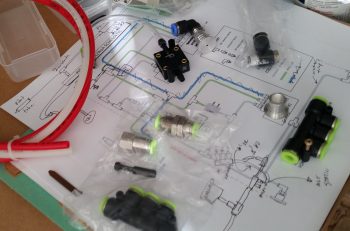

After I finished with the PQD bracket mounting on the Triparagon cross shelf, I headed out the door to an auto racing shop just across the river in Maryland that sells some high end stuff. I knew that they sold the same quick disconnect fittings that I’m using for my pitot-static system, so I wanted to take a quick break from the build and take a gander. Well, it had been raining all day, but there seemed to be a lull. So I grabbed the keys to the shed, pulled out my table saw and trimmed down the 1″ x 1″ angled 2024 aluminum extrusions that will serve as my Triparagon cross shelf mounting tab overhangs.

I trimmed these angled extrusions down on the sides that will mount to the front underside edge of the Triparagon cross shelf. I took 0.4″ off, with the obvious resulting width of the top horizontal extrusion arm being 0.6″. This took all of 10 minutes, and it actually started sprinkling again as I was putting the saw back away in the shed. With my overhang extrusions cut, I was then off to the racing shop in Maryland.

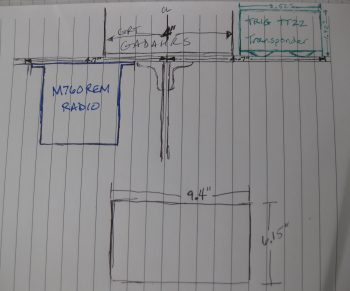

As a reminder, besides simple weight savings, I wanted to trim down the left side angled extrusion, specifically, to allow me to mount the M760REM COM2 radio about 0.4″ forward on the left underside of the Triparagon cross shelf. This served to better deconflict the mounting screw placements between the COM2 radio and the GRT GADAHRS that’s mounted on the top side of the cross shelf. The right extrusion was merely along for the ride since I might as well make them symmetrical, right?!

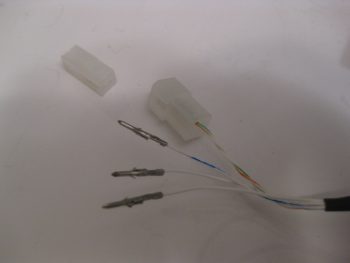

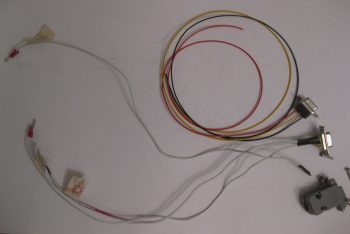

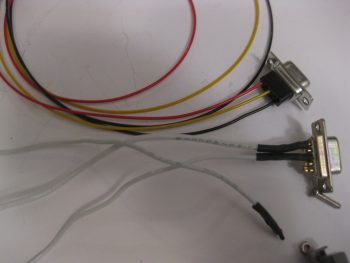

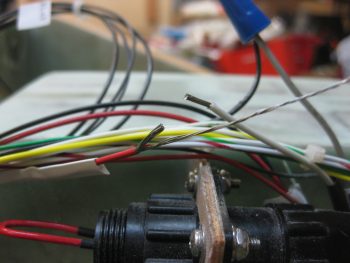

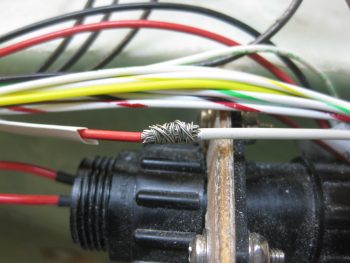

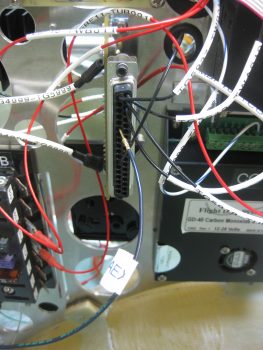

Back from the racing shop, and my quest to replace the #40 drill bit that I broke (to no avail), I got back to work. After I collected up the right sized bits for drilling the connector mounting holes into the PQD bracket, I decided to take yet another slight detour to finalize a task that needed finishing: the right-side avionics wall bracket for the P3 & P5 connectors. I drilled out the 8 total connector mounting screw holes and then did a final cleanup on the bracket by sanding down the edges and ridding it of excess glass fibers around all the holes. I then test mounted both the P3 & P5 connectors. I brought down the Trio A/P wiring harness from upstairs to test fit the other side of the P3 connector [confession time: I spent a good 10 minutes looking for that darn P3 connector just to finally realize that I had mounted it to the end of the Trio wiring harness pitch servo cable!]. You can see that I also set the 2 white auto trim wired into the back of the P3 connector as well.

Here’s a longer shot of the P3-A/P Pitch Servo and P5-Infinity Stick Grip connectors test fitted and mocked up in place.

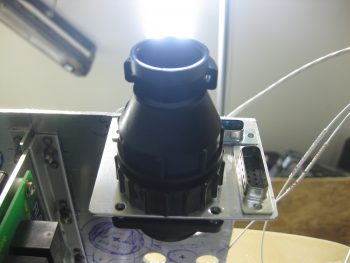

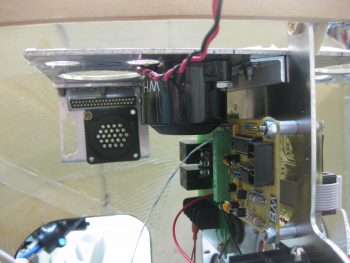

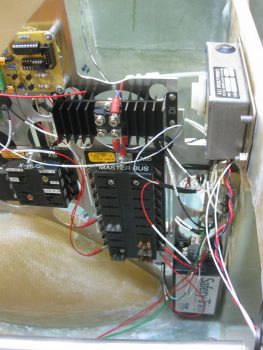

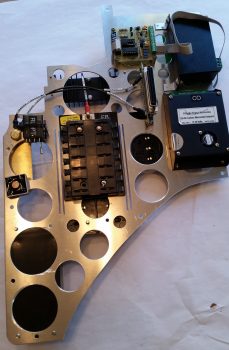

Moving on with more connectors, I then mocked up the PQD connectors P6, J3, and J4.

Since I was holding the camera down low taking low-to-high angle shots of the PQD bracket through the right leg hole, I took a few rounds to ensure that I got a good pic. I had to leave this one in the mix since it looks like something out of Star Wars with a pure beam of energy coming out of the back of the P6 connector. That’s right folks… no wires for me! Just pure energy transfer in my ship! HA!

Here’s another shot of the PQD bracket and its connectors. Note that although I originally wanted to mount the D-Sub connectors on the aft side of the PQD bracket (which would be the forward side of the plane), it initially appears that the connection hardware with the mating side D-Sub connectors will be tough to do if I left them aft-bracket-side mounted. I’ll play around with the hardware a bit, but I think that this will most likely be the mounting configuration for these connectors.

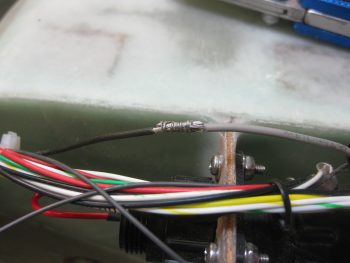

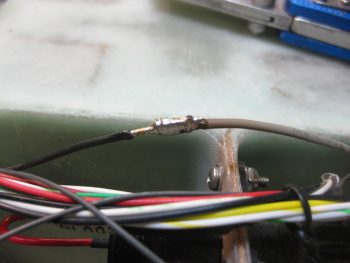

An issue that I noted was after I test fitted the aft side P6 connector’s cable clamp: Hmm, don’t think it’s going to fit since the gap spacing between the cable clamp and the panel is only about 2-5/8″. It would most likely actually fit, but then of course all the wires would exit and then immediately have to take a hard 90° turn to get to their final destination. Not good. So . . .

Be gone vile & wicked cable clamp! (said in thick British villain voice… sorry, my Brit Canardian Peeps. ha!)

Ok, much better! As you can see with the P6 connector cable clamp removed I get about another 1.5″ clearance and 4″ spacing overall. Still slightly tight, but since the GRT HXr EFIS is low profile on the backside this is EZily workable.

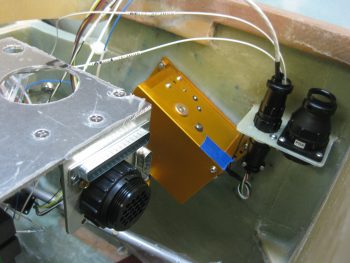

And yet another shot showing all my current Avionics Bay connectors.

I reordered my blog post pics just a bit to make the topic flow a bit EZier to follow. If you looked closely in my Avionics Bay pic above, you may have noted that I drilled a hole into the triangular panel support and added another RivNut for the second & final Adel clamp that will also be used for the Infinity Stick Grip cable routing from the stick to the P5 connector. I also added a couple of layers of BID on the bottom side of the support triangle to beef up the RivNut mounting.

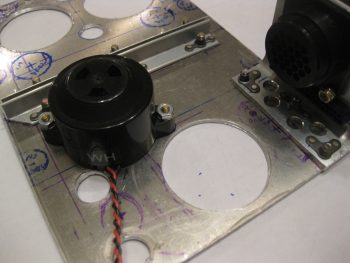

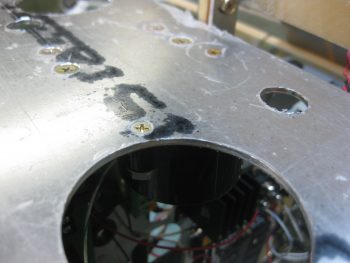

Back on the Triparagon cross shelf, with the PQD bracket configured & installed, I then started in on some of the final pieces parts (aka “CrackerJack Bits”) that I need to mount to round out the final electrical system components install on the Triparagon. I found a good spot for the Piezo Warning Horn on the right underside of the cross shelf. I mocked it up, ensuring it had good clearance with the vertical Triparagon components (it’s close to, but not touching, one of the mounting screws to the right side AG6 warning annunciator). I drilled the holes for #6 mounting screws and then countersunk the 2 screws on the top side of the cross shelf.

Here’s a closer shot of the mounted Piezo Warning Horn with the #6 mounting screws installed. I used standard nuts on the screws to mock up the warning horn & make it EZily removable.

I then test fitted the Triparagon cross shelf onto the vertical plate to double check the clearance between the warning horn and other Triparagon components. In the pic below you can see the 2 countersunk #6 screws, and the warning horn itself through the lightening hole.

Here’s a final shot of the mounted Piezo Warning Horn on the right underside of the Triparagon cross shelf (pic taken from the front of plane). You can see that it’s close in line to the wiring bundles that will spew forth from the PQD bracket, but also clearly not in the way either.

Here’s a final shot of the mounted Piezo Warning Horn on the right underside of the Triparagon cross shelf (pic taken from the front of plane). You can see that it’s close in line to the wiring bundles that will spew forth from the PQD bracket, but also clearly not in the way either.

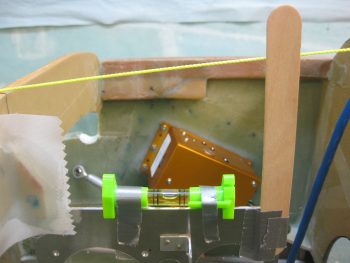

I then brought my cardboard component mockups that I made a year or so back to check out their general fit on the Triparagon cross shelf. Below you can see the GRT GADAHRS (their new term for their new AHRS) and the Trig TT22 Transponder behind the GADAHRS.

Another shot of the cardboard GADAHRS & XPDR mockups.

Another shot of the cardboard GADAHRS & XPDR mockups.

Just an idea of the fit of the Trig TT22 Transponder on the Triparagon cross shelf.

And the cardboard GADAHRS and XPDR on the Triparagon cross shelf with the rest of the left side Triparagon in view.

Since there’s forecasted high winds tomorrow, and thus no flying, I’ll continue my quest to finalize the Triparagon cross shelf and resident components install. I will be doing some more sideline wiring on my components since currently they’re EZ low hanging fruit, and don’t conflict with other parts of the build (like so many other build actions do at this point!). It doesn’t look like to much longer before I’ll be back on the . . . Yes, WHEEL PANTS!