Ok, I of course could have simply titled this “rollover assembly,” but the fact is I will have both: a rollover assembly for safety, which is essentially a 4130 steel roll bar, and also a headrest akin to the plan’s style headrest of years yore. However, the distinct difference is that my headrest will be as minimal as possible and allow as much clearance for the GIB’s unabated view as possible.

Why a headrest? There are 3 primary reasons I’m looking to incorporate a headrest into my rollover design scheme. I would say that the following list is actually in reverse order of importance:

1) Obviously the name: headrest. Not that I’ll be pulling so many excessive G’s so often that I’ll need a headrest, but I think it’s good to have one… especially when you need/want one.

2) Storage. In a small plane like the Long-EZ, you need all the storage you can get. Think of this headrest as a narrow tall box that is hinged at the top. In it will go the many things required for preflight and ground ops like a fuel sampler, rags, tie-down lines, mini-chocks, flight control gust locks/pins, etc.

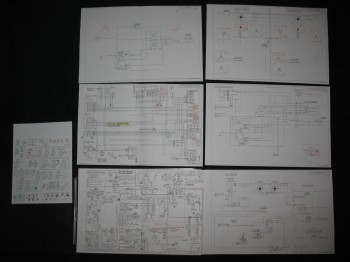

3) The Garmin GTN650 WAAS GPS stand. If you’ve happened to have installed a Garmin GTN650 recently, or simply read the installation manual, you will have noted that to reach the appropriate resistance (1.5-6 ohms) on the coax cable connecting the GPS antenna to the GTN650 head unit requires a cable length of 6.5 feet. Well, interestingly enough a cable run of 6.5 feet is spot on between the back of the GTN650 and the top of my headrest tower. In addition, the farther away it is from any electrical devices, the better.

A week or so back I measured the distance between the top of the longerons and the inside top of the canopy in the general position that I’ll have the canopy. With over 17″ of clearance for a rollbar, I figured I would go no higher than 15″, so I drew up a quick diagram noting all this.

Fast forward to this afternoon when I pulled out the Plans and discovered that Burt’s original triangular composite rollover assembly is 12.7 inches tall. I took note of this since in order to save space, and maximize the view of the GIB, I really want to be in the general ballbark of the height of the plan’s rollover. For safety I of course want it taller than my noggin, but only as tall as it has to be, no more.

With the plan’s rollover assembly dimensions in hand, I started designing my version of the headrest. One set of dimensions that I knew right off the top was those for the WAAS GPS Antenna: approx 4-3/4″ x 3″. This clearly is no compact antenna.

I had two simple overarching goals for the headrest: shorter & narrower then the plan’s version. I succeeded in meeting those goals …. sort of. My headrest tower is definitely shorter, but the top is clearly bigger since there’s a robust GPS antenna living up there. The base is significantly narrower, and even tapers narrower moving aft. With that being said, since I had 15″ of clearance, I started with an orginal height of 13-1/2″, about 3/4″ taller than the plan’s version. Of course I suspected I would shorten the model, but I wanted to see how it looked… and it’s always easier to remove material than to add.

Here’s the initial cardboard mock-up of my headrest.

Without reference it looked rather tall. I eventually whittled it down to about 11″, but then realized I needed to judge its height with it under canopy. So I put the canopy over the 11-inch version if the headrest.

Moreover, I thought it might be a good idea that before I start glassing I should see how it relates TO MY HEAD. Since it will be, in fact, a headrest. The grand payback when incorporating any mod is of course time . . . and pain. So, using some simple risk management and avoid me toppling over inside the fuselage 3′ in the air, I needed to put it on the ground. Thus, half an hour later I climbed inside to see how big my noggin really is! ha!

After messing about and playing the “I’m this tall” game with my hand against the top of my head going backwards (yes, I put the foam seat pad in place) I concluded that 11″ was just a tad too short [probably the perfect height would 12.7″… eh?!] and decided to add another 0.8″. Thus, my final height for the headrest is 11.8″ tall (0.9″ shorter than stock, but wider at the top), and 5.8″ wide at the base (vs 8.4″ wide stock) and 5.8″ deep (vs 4.5″ deep stock).

To really get an idea of the height, I Googled some pictures of the Long-EZ’s rollover assembly and watched a few YouTube videos to get a good mental baseline picture before I went final with the dimensions.

Also, to check out the very general appearance of my aft-leaning rollover bar that will encircle the rear top edge of the headrest, I balanced the rollover bar on the headrest mock-up.

Satisfied, I then started cutting out the foam for the headrest. The front & sides will be 1/4″ thick foam while the rear will be 3/4″ foam, so that I can have much larger radiused corners at the back for a more “flowing” look:

And here’s how the foam pieces looked when I pinned all the bits together with small nails:

And lest we not forgot one of the main reasons for this exercise:

A tight fit, yes, but I wanted to keep the top as narrow & small as possible.

I’m pretty happy with this headrest. It will get the WAAS GPS antenna up where it needs to be, provide much needed storage and with the taper I have set I have a great view of the fuel site gauges and it it minimizes the view obstruction for the GIB.