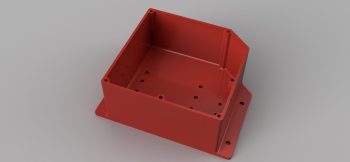

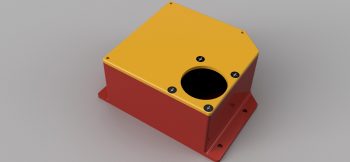

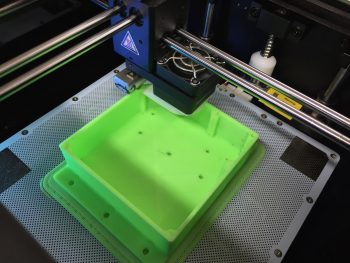

With the Nose Gear AEM box designed in CAD and sent to Marco for final collaboration and then 3D printing, I got organized to start wiring the internal components of both the RCU and the AEM. Since the weather is getting better only sporadically, with the seemingly incessant high winds as the norm, I figured I would trudge on to finish up as much of my electronics as possible until good weather allows me to fly & glass.

The first order of business was implementing the $1.49 clamp I picked up at Michael’s to allow me to employ the fixed iron method that is detailed in a Youtube video that Marco sent me, and also as I had seen prior in an EAA soldering video (featuring one my local Chapter 186 members, Dick Koehler). After using this method a bit without the clamp, I really liked it so I bought the clamp and made up my poor man’s version of it:

And here’s the YouTube video on the fixed iron method:

Ok, let’s talk about box configuration. For mainly external reasons, I needed my RCU box to be no more than 2.1″ tall internally. This meant the space for wiring connectors would be tight, and might have meant a fair amount of soldering, which as you can see above, I was fully prepared to do! ha!

Well, late last summer I had disassembled a friend’s dishwasher to get rid of it and recycle the parts. I threw the wiring harness in the garage to use for test wire (vs Tefzel) any time I needed “trash” wire. Well, I had it upstairs since I was cutting off pieces of this wiring harness to test circuits, and low and behold I found some 90° right angled 0.25″ FASTON connectors on the harness. I cut them off and inspected them closely and was able to pull away the wires’ outer insulation from the plastic retainer to reveal bright shiny copper underneath. Since the clamp part of the connector was spotless, I decided these would work great for the 22AWG ground side of the relay coils and pressed them into use. Since I didn’t have enough, I bought a few more for the relay coils’ positive terminal sides.

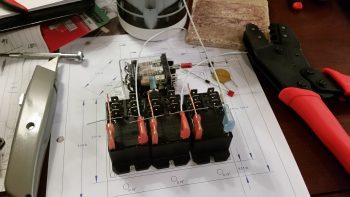

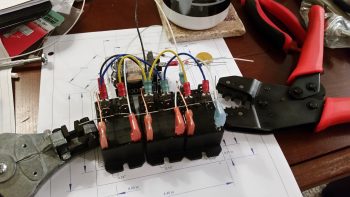

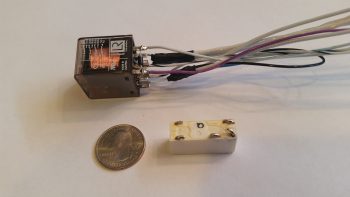

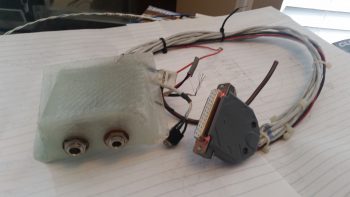

Here I’ve laid out the components further so the wiring flows in accordance with the wiring diagram. I crimped the normal FASTON terminals in place on the relay interconnect wires, first bending the terminals very slowly & carefully at a forward angle to give me just a bit more clearance under the lid. Also, you can see on the blue flag connector on the right relay that besides the 18AWG power wire, I crimped the flyback diode and 56.2 Ohm resistor into the terminal as well.

[NOTE: my relay interconnect wires came out too long –meaning too tall to fit under the RCU box lid– so I need to cut the wires shorter & re-terminate the terminals on the outside relays].

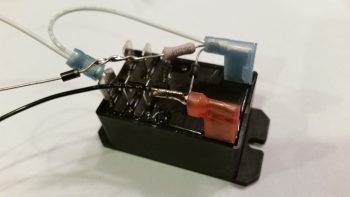

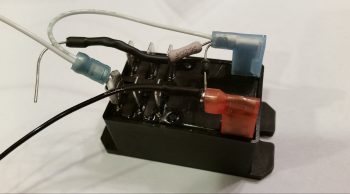

I then focused on relay #3, which is the heart of incorporating the small 1.2A backup battery into this system, as Jack has in his original nose gear system (Note: Marc Z’s version doesn’t have this relay since he uses the mechanical gear down backup system). I soldered the flyback diode in place between the relay coil tabs, then soldered the 22AWG black ground wire in place, with all this soldering taking place at the red terminal. I then soldered a Schottky diode (middle left) to the resistor going to the positive side (blue terminal) of the relay coil. This Schottky diode & resistor make up the backbone of the charging circuit for the 1.2A backup battery.

I then covered my solder joints with heat shrink tubing.

With that, I called it a night knowing that tomorrow I’ll have to cut my relay interconnects shorter and re-terminate…. (big sigh)