….GUILTY!

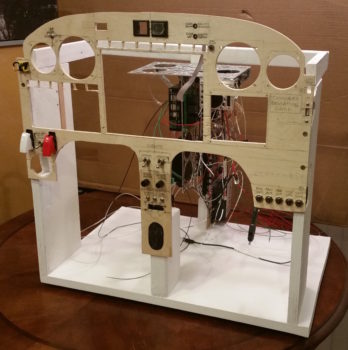

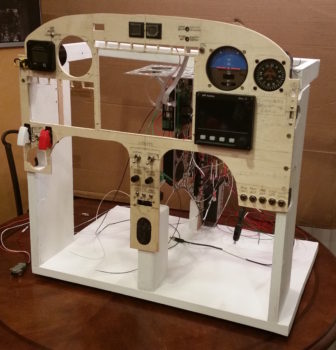

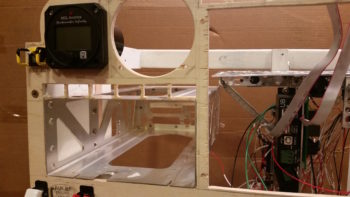

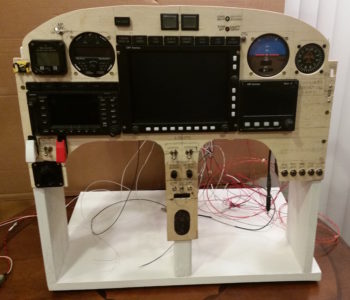

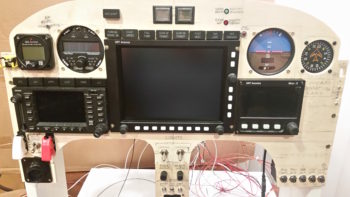

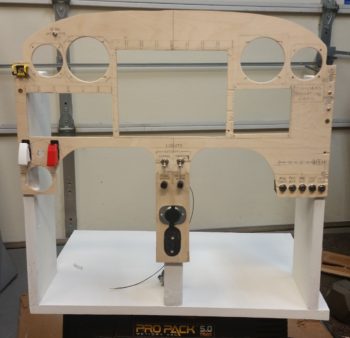

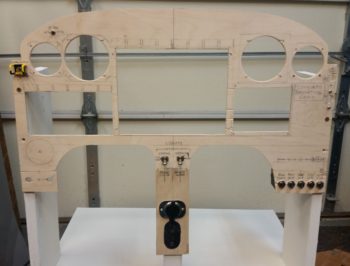

Since my last update I’ve been continuing down the path of finalizing my EFIS checklists, to include my education on how the GRT HXr, Mini-X, Trio autopilot and GNS480 GPS all play together during normal sorties, and specifically during instrument approaches.

Since the “online” checklists on the GRT HXr are simple small-sized text files, it means that A) they take up very little thumb drive space, and B) I can add virtually as many as I want. Since the integration of my glass cockpit comes with a decently high learning curve, this led me to make crib notes for the pertinent functions, especially the ones that had either befuddled or eluded me for various reasons (typically ignorance, ha). I’m seriously under no illusions, knowing that after another 6 months of in-depth building I’ll have forgotten the majority of what I just learned… thus, hopefully my crib notes will facilitate glass cockpit mental reintegration much more quickly!

Besides continuing to add to my checklist library, it also got me back into the manuals and other various reference material specifically focusing on GRT EFIS-based instrument approaches. Case in point, a gold mine I found on the GRT forum from a response that Bob Turner (resident forum non-GRT-employee EFIS guru) provided a GRT newbie was a 3-page how-to for setting up the autopilot, managing climbs & descents, shooting precision & non-precision instrument approaches, and missed approaches. The only catch was that Bob’s notes were specifically geared towards an HX EFIS, which is close to the HXr, but requires a bit more button pushing.

In addition, my first real scheduled 28-day cycle navigation data update from Seattle Avionics was due, so while I fiddled about with figuring out the idiosyncrasies –and there’s a distinct few– of that process [I tried to do it overnight as Seattle Avionics recommended, but that didn’t work…. but I think I can get it to next time] I went to work concurrently testing out Bob’s 3-page knob-twisting and button-punching EFIS how-to on instrument approaches. I finally got the multi-hour Seattle Avionics nav data download completed [this data covers approach plates, airport diagrams, sectionals and IFR low charts] and was still into documenting pertinent information nuggets into my “online” (EFIS) crib notes, and morphing Bob’s instrument approach how-to’s into a GRT HXr and Mini-X based document that I could use.

It felt good dialing in the process for getting the first set of nav data downloaded from Seattle avionics and then uploaded onto the HXr’s thumb drive. Moreover, through the process of verifying and/or modifying Bob’s procedures, I learned a ton more about the EFIS/GPS/Autopilot functions and interfaces, nav modes, approach sequencing and just general familiarity with my panel systems. Also big was my more in-depth understanding of the capabilities of my Mini-X backup EFIS. All good stuff, which of course was fed into the checklists for yet another round of updating.

To perhaps express a bit clearer on these checklists, the minor issue in updating them is one of format. I prefer, if possible, for a checklist item to only be on one line of the checklist … I guess harking back to my military days of focusing on ABC for any communication: Accuracy, Brevity, Conciseness. So, when I say format, besides optimized verbiage, I often mean the difference between a physical one or two line checklist entry can be had by denoting “on” as “ON”, “On” or “on”. Or GPH vs gph, etc. Minor issue yes, but it’s one that I simply clean up on the fly as I add more info into my online checklist/crib note library.

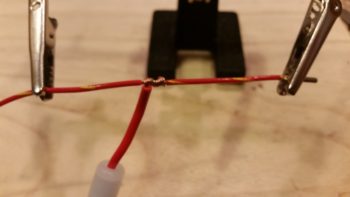

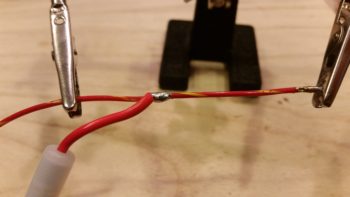

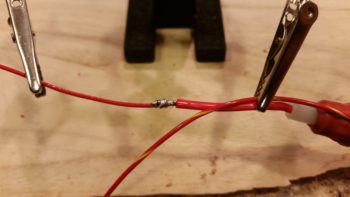

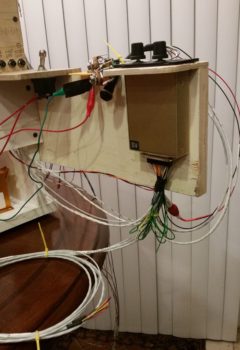

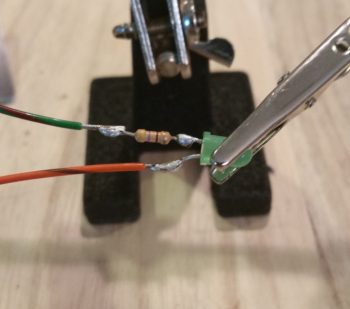

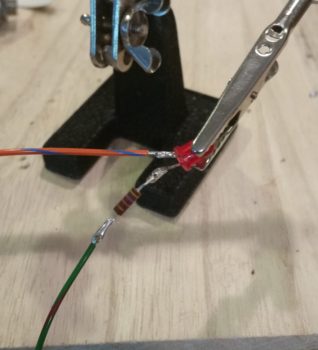

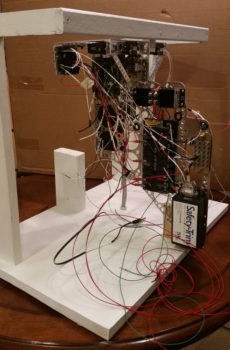

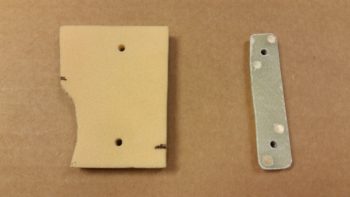

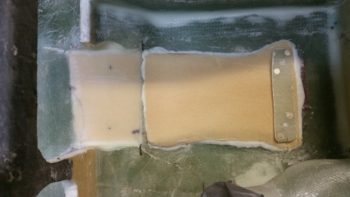

I also engaged in some direct collaboration with Eric Page, ala Aeroelectric Connection forum, on maximizing the output of a Voltage “Deslumpifier” (brown-out circuit module) based on Eric Jones’ (perhiheliondesigns.com … and one of my electrical system mentors) original design. Initially Eric came back and stated that the specs for his new & improved Deslumpifier design just wouldn’t work for the GNS480. Then Joe Gore jumped into the forum conversation and sparked an offline discussion between me and Eric on building a supercharged version of his new & improved Deslumpifier, specifically for my GNS480 configuration. Over the last two days, Eric was able to spec out some higher powered capacitors (5-Farad per) that would both fit his board and give us nearly double the output for my supercharged (in comparison) Deslumpifier. Of course the proof will be in the pudding if it actually works or not, but based on Joe Gore’s provided numbers, it looks very, very promising… and again, all for much less than TCW’s Intelligent Power Stabilizer (again, not bashing TCW– great products).

So yes, alas, I have gotten very little done in the shop. But to be honest, I don’t mind straying from the playbook a bit during the cold winter months because it does save a ton of money from having to heat up a cold shop (or try to work layups all under heat lamps). And I have to admit it’s been really gratifying digging deep into these systems and learning their true, no-kidding operational capabilities.